Aircraft Cable Management Systems: Safety in Flight

- December 14th, 2023

- Categories: Uncategorised

Commercial aircraft are complex machines that need a combination of intricate systems, including cable management systems, to function safely and efficiently. From safety to maintenance, technical operation and performance, cabling plays a vital role in various aviation industry sectors.

Depending on the model, size and scale, an average airliner can contain up to 600 km of wiring. This wiring network helps to interlink a wide range of important equipment together. Strong cable systems, for instance, assist with avionics, data, power, sensor information, inflight entertainment, flight control, and emergency lighting.

Whether you have a team of aviation experts or fly commercial aircraft, managing these cables can differentiate between a smooth and dangerous flight paths.

The Importance of Cable Management in Aircraft Operations

Why is cable management so important? The process needs to be precise, organised, and safe when integrating wires and cables throughout a plane. The proper management of this system ensures that the aircraft meets the necessary standards.

What Is a Cable Management System?

Ever wonder how commercial airliners run electricity? A cable management system covers electrical, mechanical, and data cables essential for successful navigation, signal transmission, communication, and control systems.

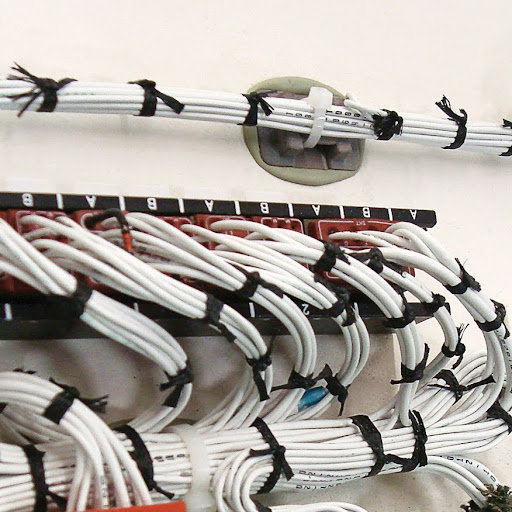

These cables are controlled by a series of cable ladders, cable trays, and cable baskets, which protect the cable system from entanglement and damage. This framework also prevents any disruption to onboard functions and electrical hazards to the flight crew.

A well-designed system allows for easy maintenance and troubleshooting. Without a safe and effective framework, there would be system failure.

Benefits of Cable Management Systems

Wire systems are specifically designed to improve the performance of an aircraft. Put simply, an aircraft cannot function without a fully operational cable management system.

To carry out its core purpose and function, the cable system must be able to complete the following functions.

Maximising signal transmission

Well-organised and arranged wiring will prevent electrical interference. In addition, it will also facilitate uninterrupted communication that allows pilots to navigate and control the aircraft safely.

Streamlining diagnostics

Proper diagnostic procedures enable technicians to identify, access, and address existing and future problems. Therefore, a safe and well-managed cable management system allows aircraft technicians to carry out repairs and routine checks more easily.

Ensuring durability

A cable management system not only enhances the performance of an aircraft but also reduces wear and tear over time. In turn, this works to create a viable system that is durable and long-lasting.

Environmentally friendly

The aviation field creates a lot of pollution, and modern cable systems can reduce this fuel consumption. Since wiring may account for up to 3 per cent of an aircraft’s weight, an innovative approach to wiring systems can reduce drag, meaning that it won’t resist its motion forward through the air.

Compliance with regulations

Cable management systems must comply with regulations set by the Civil Aviation Safety Authority, which dictates these cables’ design, installation, and maintenance. These regulations provide a detailed framework around safety, specifications and other technical aspects.

Want to learn more about aerospace? Check out how ERG materials advance the aerospace industry.

Types of Aircraft Cable Management Systems

If you want to organise, protect, and boost your aircraft performance, there are types of wiring systems available. Let’s give a brief rundown of them now.

Lacing and tying

This is a traditional wiring method that involves manually tying cords together. Although more labour-intensive, it is often more effective than current methods.

Cable clamps

Cable clamps are mechanical devices used to clamp down wires to aerospace structures. They are generally made from metal or composite and come in various shapes and sizes.

Bundling sleeves

Bundling sleeves are used to group cables, ultimately protecting them against chemicals, abrasion, and moisture. Overall, bundling sleeves are designed to enhance the operational efficiency of wire systems.

Cable raceways

As enclosed channels, cable raceways can protect cables along a routing path, commonly installed on aircraft structures requiring additional protection.

Cable troughs

As open channels, these wire systems work as a guide to specific directions and are similar to raceway systems.

Cable clips and clamps

Designed to secure cords to aircraft surfaces, cable clips can prevent these from moving or rubbing against other wires.

Cable entry systems

Providing a sealed entry point stops cables from being exposed to the environment, such as cold weather or chemicals.

Wire ducts

Rigid and flexible wire ducts easily route cables while also protecting them from damage. If you want to learn more about tooling used to build aircraft, consider comparing the e-drill 2.0 system vs. hand-drilling.

Cable identification solutions

Labelling cables is essential for the maintenance and troubleshooting of airport technology. Adhesive labels, heat shrink labels, and laser marking are the most commonly used techniques.

3D Models for Simulated Flight Testing

Simulated 3D Model flight testing can assess an aircraft before it takes flight. Technicians can use this to evaluate performance, predictive maintenance and characteristics, and understand system behaviour in a controlled environment. So, what is involved in this process?

- Early design assessments. Assessing aerodynamics and aircraft designs in the early stages allows engineers to point out issues before making virtual prototypes. Engineers don’t need to solve issues once a final prototype has been created because it will be ready to fly.

- Cost and time. As a simulated flight test can cut costs with manufacturing and design, it is worth testing these advanced technologies.

- Safety. Compared to traditional flight testing, a simulation allows engineers to understand, analyse, and fix aircraft performance issues without replicating real-world flight. There is zero risk of emergencies.

- Data collection. Data such as aerodynamic forces, structural loads, and system responses can support engineers with their current and future projects.

Regulations Governing Aircraft Cable Management Systems

According to the Civil Aviation Safety Authority, hazard identification and management in the aviation section state pilots must maintain a clear idea of current, emerging hazards and associated safety risks.

Regulatory bodies Aerial Application Association of Australia and the Australian Transport Safety Bureau suggest strategies to prevent wire strikes. Set client expectations, conduct a briefing of an area before the flight, reassess risks when plans change, avoid distractions, don’t rely on reaction time, and always have a system to change electrical wires.

Apply Flight Safety With Aircraft Cable Routing Systems

At Applied Fasteners and Tooling, we prioritise flight safety for industrial sectors for both technicians and passengers alike. We stock Hi Lok Fasteners, Grip Lock Ties, Cable Tie Mounts, Click Bond Fasteners, Aerospace Tooling, and Cable Management Tooling for your convenience.

Whether you need to reduce maintenance costs, control surfaces, track real-time data or request guidance on a new electrical system, contact us today to explore a range of services available. Directed towards engineers, we understand the need for products strong enough to withstand the elements.