Understanding the Basics of EMI/RFI Shielding: How It Works and Why It Matters

- July 30th, 2024

- Categories: Uncategorised

Electrical equipment is frequently used in our everyday lives, from smartphones to tablets (occasionally, old-fashioned radio!). However, EMI (electromagnetic interference) or RFI (radio frequency interference) shielding also plays a big role in automotive, medical, telecommunications, and aviation, and this market continues to expand.

According to this market report, the global EMI shielding market is estimated to reach USD 9.4 billion by 2028. This growth is due to government regulations and standards, product launches and developments, and established manufacturers in China and Japan.

This article will be your comprehensive guide to EMI/RFI shielding, the various types on the market, and why protecting electromagnetic fields is so critical for heavy-duty fields that rely on concrete security measures.

What is EMI/RFI Shielding?

Radiation can affect other signals from an electronic device as it travels from a circuit or device, disrupting data so it is incomplete when sent. These interferences affect the performance of circuits and turn sensors, signal receivers, and transmitters. Let’s look at some key points that define EMI/RFI shielding:

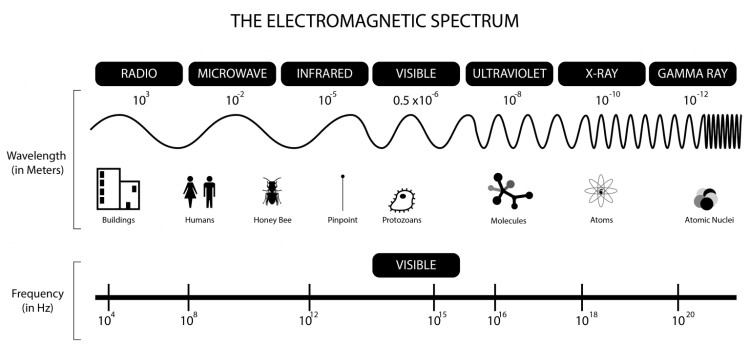

- Electromagnetic radiation (EM) consists of waves of alternating electric and magnetic energy, and the frequency of each wave (how often a new wave is produced) is related to the size of the wave. A higher frequency (which is faster) equals a smaller wavelength.

- Military, medical, and aircraft equipment and vehicles are incorporating more electronics that become smaller in size and increase in speed (due to faster processors), and EM frequency shoots up while wavelength goes down.

- All electronic communication devices produce radiation that falls on the electromagnetic spectrum when operating. Subsets of this spectrum are the radio wave and microwave ranges, frequently used with printable circuit boards (PCBs) and communication and safety devices in vehicles.

Types of EMI/RFI Shielding

What are the different types of EMI/RFI shielding? When using high-security electronic equipment in the military, for example, these industries must be protected from external sources and threats.

Radio Waves

Radio waves use voice communications, data transfers, and radio broadcasting with a wavelength range of 10mm or longer.

Radio frequencies are used with radios, cell phones, Wi-Fi, power lines, or signal cables within devices. They have wavelengths between 1m and 100 km and frequencies between 300 GHz and 3 kHz.

Microwaves

Used as a heat source for the microwave in your home, microwaves are also used for applications using navigation or radar systems. They have wavelengths between 1 m and 1 mm and frequencies between 300MHz and 300 GHz.

Infrared

Infrared is used for heat-sensitive thermal imaging, heat sources, and therapy with a frequency range of 30 THz to 400 THz, with a wavelength of up to 740 nanometres.

Visible light

Used as light sources for visibility, lasers, and electronic screens, the frequency range is 400 THz to 800 THz, with a wavelength from 740 nm to 380 nm.

Ultraviolet waves or sunlight

Used for microbe elimination, sterilisation, or UV lamps for tanning beds, the frequency range is 8 x 10^14 Hertz (Hz) to 3 x 10^16 Hz, with a wavelength of 380 nm to 10 nm.

X-rays

For internal medical examinations, art, and quality control, X-rays give a frequency range of 3 x 10^16 Hz to 3 x 10^19 Hz, with a wavelength of 10 nm to .01 nm.

Gamma-rays

Used for cancer treatments, nuclear warfare, and aerospace telescope technologies, gamma radiation has a frequency range of more than 10^18 Hz with a wavelength of less than 10 picometres (pm).

If you are attempting to prevent EMI, it is important to understand the energy you want to block. This is because different material types are more effective at stopping certain kinds of energy. For example, if you use a perforated shielding medium, the holes must be large enough for energy waves to escape.

What is The Market?

Cell phone towers, radio, or sources within devices (microprocessors) can cause interferences due to electromagnetic and radiofrequency radiation. Vehicles, 5G networks, and other consumer products also commonly use “smart” features and built-in electronics.

There are more radiation sources and components vulnerable to interference malfunction. With this in mind, let’s look at some EMI/RFI shield uses.

- Vehicle components. For example, non-metallic components such as panels and bumpers are non-conductive and cannot protect against external EMI sources. On the other hand, electric trains include more control units and sensors, meaning more components are sensitive to EMI attacks.

- 5G networks will continue to grow, and environmental or EMC regulations will change, requiring stringent EMI/RFI shielding measures.

- Electronic and sensor-based features are in most vehicles: convenience features such as GPS navigation, touchscreen informational systems, hands-free features, Bluetooth, or safety features like terrain management, parking assistance, adaptive cruise control, and more. All of this can emit and can be affected by electromagnetic radiation-based interference, which can be safeguarded with EMI shields.

- The demand for autonomous or semi-autonomous vehicles, since they protect passengers, depends on the functioning of sensors and electrical components. Shielding ensures that vehicles work as intended. For example, communications between a LIDAR object-detection camera and an ECU are responsible for controlling the direction of movement and speed and are just as important as the brake pedal.

Importance of EMI/RFI Shielding

Without EMI/RFI shielding, our electronics would stop working altogether. The goal of an electromagnetic shield, therefore, is to isolate a device’s energy so it doesn’t affect anything else and blocks external energy from getting in. Here is what proper EMI/RFI shielding can prevent:

- Electrical fast transitions or EFTs. If you’re dealing with a power outage, a transfer sequence and start receiving power from a generator. If there is EMI along with this EFT, you can experience unwanted electrical fast transitions.

- Static on phone lines. The layer that covers your phone wires is a metallic foil or metallic plaited braid that protects the lines against EMI. This type of RF shielding cuts back static during phone calls.

- Power faults. As an abnormality in any electrical current, these short circuits are a great example of a power fault, which is caused by an EMI.

- Brownouts and blackouts. A blackout is a full power outage, whereas a brownout is a partial service outage. Both are not limited to power outages, and EMI/RFI shielding can prevent this.

Types of EMI/RFI Shielding

It is commonly made of copper, brass, nickel, steel, tin, or silver, and the choice of materials includes balancing metal characteristics (permeability, conductivity, solderability, weight, and thickness) to create the best protective shield within time and budget constraints.

The material’s ability to reflect radiation depends on the wave’s impedance (how much it opposes the flow of the current) compared to the shield material. The greater the difference, the more reflection and protection. What are some things to note?

- Electrically dominant incident waves have high impedance and lower conductivity and are countered best by highly conductive materials such as silver, copper, or brass.

- Magnetically dominant incident waves have low impendence and higher conductivity, so they must be countered by absorption or suppression of radiation by high-permeable steel or stainless steel.

- The “skin effect” is where only alternating currents are impacted. Crowding on the top layers of the conductor (closer to the surface) increases current density in that material area. This increases the current’s impedance and lowers the conductor material’s conductivity.

EMI Shielding Devices

What are some common EMI shielding devices? There’s many applications for each device, so let’s take a quick look.

EMI coatings

Almost like paint mixed with conductive metals that form a shield, coatings are very flexible as they only need to be painted onto a surface to work. Taking up no extra space, EMI coatings have zero added weight. However, it only takes one scratch to compromise protection.

EMI enclosures

As the simplest type of shield, EMI enclosures create a Faraday cage effect by surrounding the equipment it protects. However, Faraday cage enclosures add weight to the device, so they’re impractical for small devices such as computer components and phone tablets.

For example, a microwave uses a perforated enclosure so you can see inside, but the holes are too small for radiation waves to escape. Additionally, EMI gaskets of conductive rubbers or metals can shore up gaps between enclosures and equipment, offering comprehensive protection.

EMI filters

Blocking higher frequencies, EMI filters allow lower frequencies to pass through and are built into the power sources or switches they protect. Filters don’t block all EMI, so you can only use them in certain situations.

Foil shielding tape

Foil shielding tape uses thin pieces of conductive metal with an adhesive to shield electronics. It is easy to use, flexible, and form-fitting. Lightweight, you can cut it into any size or shape, and it’s a great choice for electronics. Use foil tapes in copper, lead, aluminium, stainless steel, and silver, and consider the tensile strength to avoid damaging the shield.

If you would like to learn more, have a look at the critical role of EMI/RFI shielding for military defence and how it can strengthen your security measures for your next mission.

Applied Fasteners and Tooling: Secure EMI/RFI Shielding

Registered and AS9120 quality certified in 2014 and Quality Assurance Procurement Requirements, Applied Fasteners and Tooling supply the aerospace and defence industries with specialised fastening products and technical support.

Emerging as a leader in the fastening system supply chain for critical markets, AFT pushes the boundaries of what is possible.

With a wide range of shielding materials for electronic components, contact us today and shop in stock for custom product solutions. Whether you need Grip Lock Ties, Honeycomb Inserts, Ball Lok Pin, Cable Tie Mounts, Hi Lok Tooling, or aircraft tools, we are your reliable partner for fastening and tooling needs.