A Comprehensive Guide to the Different Types of Quick Release Pins in Military and Aerospace Applications

- September 25th, 2024

- Categories: Uncategorised

If you operate in the aerospace or military sector, strength and precision are something that can never be compromised; especially when it comes to the components of helicopters, military vehicles, and more.

Today, we’re going to highlight the work of Jergens a company that produces high-quality quick release pins for a wide range for heavy-duty applications. As efficient fastening solutions that are reliable and versatile for any project, this blog will be your comprehensive overview of quick release pins and their essential applications in fields where durability is non-negotiable.

Jergens : A Brief Overview

Jergens Inc., based in Cleveland, Ohio, is a U.S.-based manufacturer known for producing high-quality standard components, work holding systems, and lifting solutions. The company serves a wide range of industries including aerospace, automotive, and defense, offering precision-engineered products such as quick-release pins, hoist rings, and threaded inserts.

Jergens Kwik Lok pins

Designed to provide quick, secure, and easy locking and unlocking of components (known as self-locking pins), Jergens MS (Military Standard) ball lock pins are precision-engineered to comply with strict military specifications and meet the highest performance and quality standards. These pins are divided into three main categories:

- Kwik Lok quick-release pins – single acting. Standards and special sizes are available under NAS1333-NAS1346.

- Kwik Lok quick-release pins – double acting. Specifications MIL-P – 23460 and available under NAS133-NAS1346.

Some of the key features of these pins include:

- Kwik Lok pins offer versatility, as they are available in various sizes and configurations. They can also be customised to suit project requirements and are used for fixing, locking, connecting, adjusting, and quick-change positions.

- Kwik Lok pins have a push-pull mechanism, allowing for lightning-speed engagement and disengagement when necessary, improving operations within the military and aerospace fields.

- Kwik Lok pins are corrosion-resistant and made from stainless steel and other high-strength alloys, making them suitable for harsh environments.

- Manufactured with tight tolerances, ball lok pins ensure a reliable, precise fit and performance for critical applications, such as securing military weapons

- T-handle, safety handle, mushroom handle, elastic handle, standard handle and combination handle come in four colour variants: grey, black, blue, and orange.

Types of

Kwik Lok Pins

Now that we’ve had a brief overview of what Kwik Lok pins are and the purpose they serve, let’s look into the different types. More specifically, we will explain how they are beneficial to the military and aerospace industries. After all, safety is paramount in the defence field.

Reach out for personalized support and innovative solutions for your aerospace and defense projects.

Quick Release Pins

Also called detent pinks, quick-release pins are hand-operated, non-threaded cylindrical fasteners that are simple to operate. They are typically inserted into one or more holes to fix a component’s position and join components. This helps to achieve a steady alignment between both components and is helpful for assemblies that need to be frequently adjusted.

Quick-release pins can be used for holding shear loads on plated steel or stainless steel apparatuses, fast assembling, disassembling, or applying a locking action.

: Quick release pins are classified into positive locking pins and push-pull pins.

- Positive-locking pins include a locking action independent of the removing and insertion forces. These are push-button devices that incorporate a solid stainless-steel spindle, securing the ball on its extended position. For example, a 1/2″ 17-4, 2 ball pin is rated at 1,160 pounds of pull out strength, and heavy-duty cotter pins use a forged, high-carbon steel body and a locking action offered by a tempered steel snap ring mounted on the head of the pin.

- Push-pull pins are often made from a solid shank or hollow with a ball, locking lug and a button backed up through a strong plus, core, or spring. These are undersized to fit different hole-drills to the normal diameter sizes.

What are these pins used for?

Quick release pins are most commonly used to fasten, locate, adjust, remove, and align accessories on equipment. If an object needs to be released quickly without difficulty (such as a fire extinguisher mounting bracket), a ball lok pin makes this process seamless.

- In aerospace, quick-release pins support engineers with a variety of different functions, such as holding components in place, quickly assembling modular systems, and preventing accidental release under high-stress conditions. They are also used in adjustable equipment such as seating and cargo systems, as well as to facilitate quick changes to setups during testing procedures.

- In the military, ball-lok pins secure components such as sights and barrels, hatches and cargo racks on military vehicles, rapid setup of portable shelters and communication systems, as well as aid repairs or maintenance work to military equipment.

Detent Pins

Detent pins are a specific style of quick release pins that have springs within the pin shaft. They are also used to apply force on two ball bearings that extrude into the pin holes. Locking firmly as it is inserted into the locked position, detent pins only need a pull to release! The cross hole can be drilled part way with the pin while the spring and the ball are pressed down, then you can swage the hole and pull it free with little force.

With this low release force, they are available in different custom and metric sizes, standard diameters from 3/16″ to 3″, made from 300 Series stainless steel, 4130 alloy steel, and stress-proof alloy.

Detent pins are economical, especially for military operations. They allow for flexible configuration based on military mission needs, facilitate quick maintenance in the field, help with weapon positioning, secure military equipment such as doors, hatches, panels, and lastly, provide ease of use for a range of military operations.

L-Handle Quick Release Pins

Made in different sizes, L-handle quick release pins are manufactured with durable corrosion resistant materials and feature some of the most innovative designs on the market today.

Their stainless steel materials (including chrome or a polish-plated finish) make them excellent for yachts, helicopters, aircraft, military vehicles, and motorsport cars that rely on high performance on the track.

Marine Pins

Next we have quick-release pins that include a recessed button handle-style pin, which is designed to avoid accidental actuation of the pin, making them ideal for applications that need small clearance around the pin.

The detent style offers a practical pull-and-push action where minimum tension loads are needed. Marine pins provide consistent, repeatable performance for aerospace and military applications.

How are quick release pins measured?

When it comes to making use of their functioning, you need to be aware of how quick release pins are measured.

For example, the ring-style quick-release pins are plated steel materials and stainless steel locking balls. In this case, the diameters fit the normal drilled holes in commercial tolerances. You can use a 2.1 grip length for 2″ thickness material.

If you’re an engineer requiring support for automotive systems or marine environments and are looking for alloy steel or stainless steel pins with corrosion resistance in compact sizes, AFT is a reliable supplier.

Reach out for personalized support and innovative solutions for your aerospace and defense projects.

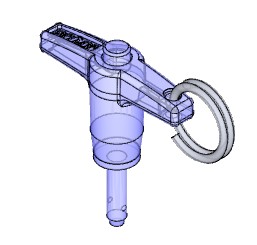

Quick Release Pin – The Components

How does a positive locking pin work for military and aerospace applications? Let’s look at its components!

- The head, which holds the button, is available in different shapes for many applications

- The button sits on top of the pinhead, controlling the pin’s locking mechanism.

- The ring attaches to the head, but it is optional. Connect a tether to the ring and an element of the application.

- The internal spindle moves with the button and is just above the ball locks.

- The internal spring compresses when the button is pushed, forcing the internal spindle down.

- The pin shaft houses the internal spindle and balls.

- The retaining ring shoulder creates a barrier against the internal spring, pin shaft, and is within the head.

- Ball locks protrude from the pin shaft, locking the pin in place and housed within the pin shaft.

Approved by the Victorian Defence and Space Network, AFT follow quality assurance and procurement requirements, so it has never been easier to find custom solutions for ball lok pins!

Quick Release Pins: Aerospace Fasteners for Operation Efficiency

Emerging as a leader in the fastening system supply chain, Applied Fasteners and Tooling was founded in 2014 to supply the aerospace and defence industries with quality, specialised fastening products and technical support.

AS9120 quality certified, AFT offers extensive support throughout the design, procurement, production, quality, maintenance, and repair, a partner known for our responsiveness, collaboration, flexibility and on-time delivery for all fastener and tooling needs.

Whether you need to order AN, MS, and NAS Hardware, Cable Tie Mounts, Motorsport Fasteners, Drilling Equipment, Rivet Tooling, Cold Working Fasteners and Tooling, Hi Lok Tooling, or other brands’, we help a number of critical markets achieve their goals.

Request a quote, shop in stock, and contact us today if you have a custom order in mind.