Exploring The Uses of Cable Tie Mounts

- January 23rd, 2024

- Categories: Uncategorised

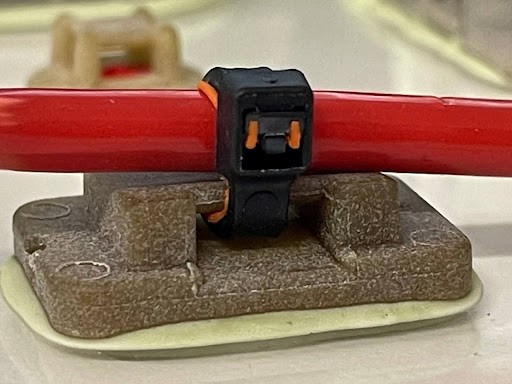

Cable tie mounts are an innovative product for a range of applications, providing proper cable management to aviation, electrical, industrial, mining, transport, motorsport, and marine industries. A cable tie mount is a convenient tool, time and time again used by professionals in these critical sectors who rely on them.

This article will explore the uses of cable tie mounts and their benefits in heavy-duty industries, guiding you towards the best cable tie mount for your next project. After all, a field mission – land or water– requires only the best.

Benefits of Cable Tie Mounts in Different Industries

There are many benefits to businesses that rely on strength in harsh conditions. Here’s a list of different industries that use cable tie mounts and the applications they’ve proven beneficial for.

- Cable management for aviation. Organising wiring systems is essential to passengers’ and engineers’ safety. Cable tie mounts are a structured, efficient solution to prevent tangling, electrical malfunctions, and risk of accidents, keeping cables secure.

- Vibration control in motorsport. Cable tie mounts assist the stability of wiring systems, prevent damage by vibrations during high-speed racing, and safeguard electrical connections.

- Cable management in mining operations. Cable tie mounts are resilient in harsh mining conditions, securing cables and reducing wear and tear. It is a long-lasting option to help keep mining machinery running smoothly.

- Organisation in the transportation sector. An organised cable management system contributes to lighting, communications, and control systems for transport, stabilising the fastening of cables during transportation.

- Environmental resistance in the marine sector. With constant exposure to the elements and corrosive seawater, cable tie mounts resist corrosion, assisting cable management for ships and marine vessels.

Understanding Cable Mounts

Cable tie mounts are renowned for their simple uses in the practical field, but what are the different types of cable mounts, and how can they assist important projects such as military missions?

1. Adhesive cable tie mounts

As the most commonly used type of cable mount, these secure cable ties are a reliable mounting solution. Strong adhesive backing provides excellent bonding strength to wood, plastic, and metal materials. Made from durable composite materials such as UltemⓇ, they are high-performing even in demanding environments.

Available in different sizes to accommodate different cable tie bundles and widths, adhesive cable tie mounts are simple to install. Use them for automotive wiring or industrial cable management to stay organised!

2. Heavy-duty adhesive cable mounts

Heavy-duty cable mounts have increased tensile strength and are often used in construction, telecommunications, and electrical installations. If an application requires something stronger, keep cables in place; these will work brilliantly in military applications.

These mounts are built from UV-resistant UltemⓇ or stainless steel and feature a larger surface area than standard mounts.

3. Screw-mount adhesive cable ties

Other types of mounts, such as screw-mount cable ties, are designed to be attached to surfaces via screws, providing a secure hold for applications that may require to be moved frequently.

Made from stainless steel or nylon, screw-mount ties feature pre-drilled holes for easy installation using screws. Additionally, adhesive backing and screws combined offer stable mounting options that handle tough conditions, such as timber applications.

A Step By Step Guide to Using Cable Tie Mounts

Cable tie mounts are excellent for defence, aerospace, and military applications due to their straightforward installation. What steps must you take for a secure installation?

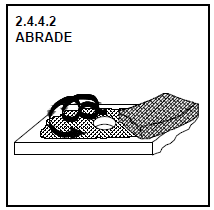

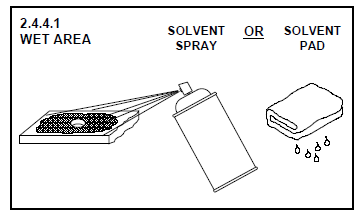

- Prepare the mounting surface.

Always make sure the surface is clean, dry, and free of any dust or debris, as this will assist the adhesion of the mount. Generally, a solvent wipe, light abrasion and a final solvent wipe will suffice.

- Peel away the backing.

Some adhesive mounts have mounting brackets with 3MⓇ tape that will hold the bracket or fixture in place while the adhesive cures.

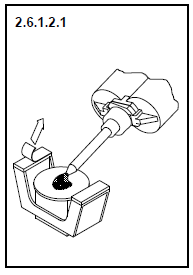

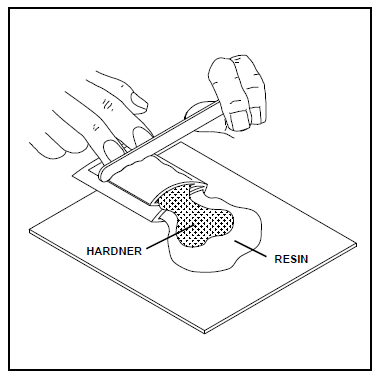

- Mix or dispense your adhesive onto the base of the mount.

- Position the mount correctly.

Place firm pressure on the desired location, positioning the mount correctly for adhesion.

- Allow time for curing.

The adhesive needs time to cure and bond with the adhesive. Always follow the manufacturer’s instructions for a recommended curing time. The usual minimum time for curing is 20 minutes.

Want to learn more about the advantages of reliable fasteners and tooling? Have a look at the Applied Fasteners and Tooling YouTube channel with training videos on bonding cable mounts or the Applied Fasteners and Tooling website!

Industries That Use Cable Mounts

Cable mounts are essential for organisation, safety, and an efficient working environment. What industries benefit from these cable mount ties and why?

Automotive

Mechanists, electricians, and automotive enthusiasts benefit from using cable mounts. Use to route and secure vehicle cables, organise, and prevent tangling and interference with components.

Construction

Cable mounts prevent tripping, reduce cable damage, and ensure a safer work environment. Cable mount ties can be used for electrical wiring, HVAC systems, and data cables, providing a reliable way to manage cables in construction sites

Telecommunications

Effective data transmission is in high demand, and the telecommunications industry organises and secures network cables. Telecommunication towers, data centres, and office spaces often use adhesive zip mounts for maintenance.

Electrical installations

Adhesive bonded mounts provide critical cable management in commercial, residential, and industrial settings. Securing electrical cables stops them from becoming tangled or damaged and helps to identify specific cables, aiding electricians in repairs and maintenance.

Proper Cable Tie Mount Maintenance

Maintenance is crucial to their long-term use for cable tie mounts to be effective.

- Choose the correct type or size. Consider weight, cable size, environmental conditions, and whether they perform well for the intended application.

- Clean the mounting surface. Using an alcohol or mild detergent to remove grease or dirt, cleaning cable ties offer maximum adhesion and prevent loosening over time.

- Avoid excess tension. Avoid applying extreme tension to the mounts, as doing so with cable ties can cause the mount to detach from the surface and affect the adhesive bonding or, in some cases, break the cable tie and possibly damage the cable.

- Always maintain and inspect. Check if there are any signs of wear or tear, replacing mounts that show signs of deterioration.

Are you looking for quality tooling in the aerospace industry but need a trustworthy supplier? Check out the importance of ERG materials in advancing aerospace technology on the Applied Fasteners and Tooling website.

Using Cable Tie Mounts – Mistakes To Avoid

Although cable tie mounts are versatile, there are a few things to avoid. After all, they need to be strong enough to secure wires for critical applications.

- Overloading the mount. Adhesive cable ties have a maximum weight capacity; exceeding this limit can damage wiring or mount failure.

- Using the wrong adhesive type. The adhesive mount must be compatible with the source material as it can create poor adhesion and lacklustre performance.

- Ignoring environmental factors. Cable tie mounts will often be exposed to challenging environmental conditions, and moisture, extreme temperatures, and UV exposure can reduce adhesive performance.

- Incorrect surface preparation. Failing to clean and prepare the mounting surface can result in poor adhesion and early failure of the mount.

Click Bond UltemⓇ Applications in Vehicles

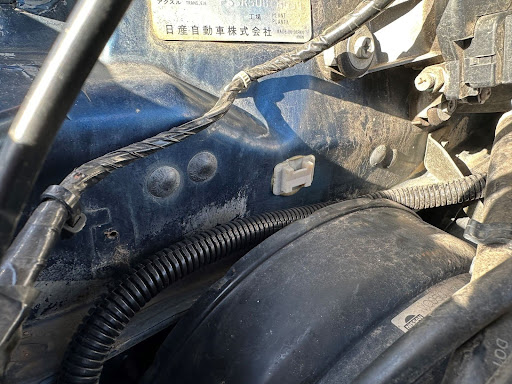

In the motorsport industry, cable tie mounts are beneficial on the road, doing much more than keeping important parts together! In this case, how do Click Bond cable tie mounts help?

- Bonded mounts for cable mounts on panels. Instead of traditional welding methods, bonded mounts prevent fracture stress, improve service life and stabilise insulation materials in a vehicle.

- Bus insulation. Supporting Internal Insulation Click Bond mounts keep Insulation in place without welding or drilling holes.

- Electrical systems installation. Click Bond cable tie mounts are incorporated to keep cables, wires, sensors, lights, and horns secure and working for the safety and security of the vehicle. This is one of their most common applications for all types of vehicles.

- Vehicle water and gas pipelines. With high vibration and weight in these applications, bonded mounts provide sealing and safety for pipelines.

Applied Fasteners and Tooling – Choose Aerospace Fasteners

Are you a mechanical engineer searching for a cable tie solution for your bundles of wires? At Applied Fasteners and Tooling, we have everything you need for aerospace and specific engineering applications, including Cable Tie Mounts, Hi Lok fasteners, AN fasteners, MS fasteners, Grip Lock Ties, Avibank Ball Lock Pins, Click Bond Fasteners, Adhesives and Equipment and a range of handy tools for your upcoming project.

We supply quality fasteners and assembly tooling consumables worldwide to the space, defence, industrial platforms, marine, transport, and aerospace industries. We provide several cable tie mounts and kits from trusted brands such as Click Bond.

Registered and AS9120 Qualified in 2014 by approved standards, we supply the aerospace and defence industries with specialised products and trustworthy technical support. All parts are supplied with certificates of conformance to customer requirements. You don’t need to stress about your design and manufacturing operations with us.

Our services cover application engineering support, product development and training, product testing, program management, and repair and maintenance support.

Contact us today to explore the boundaries of what is possible!