GripLock Ties vs Traditional Zip Ties: A Comprehensive Comparison

- May 23rd, 2025

- Categories: Uncategorised

In aerospace, defence, and advanced manufacturing, fasteners and tooling directly impact safety, reliability, and operation, so you need to carefully consider what you use.

Traditional zip ties have been a popular go-to for cable management, but alternatives like GripLock Ties are high-performing and versatile for applications that require the best in quality, innovation, and strength.

This detailed comparison explores the technical specifications, advantages, limitations, and industry applications of both fastening options. With all of that in mind, which zip tie should you use in your engineering project?

What Are GripLockTies?

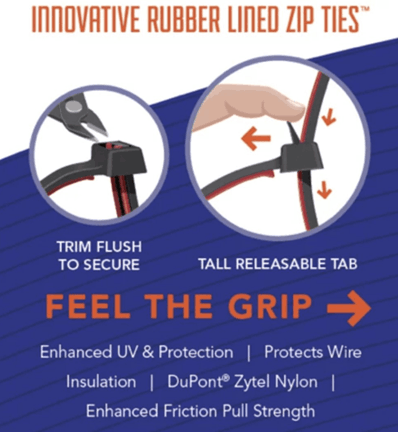

If you compare them to standard zip ties, GripLockTies offer an incredible level of strength. The rubber-lined interior improves grip and provides extra protection for cables and wires.

Here is why you need GripLockTies for demanding environments!

They are releasable

Easily release GripLockTies with your thumb by opening the big releasable tab. You can add another wire to your bundle or use one to temporarily wrap up electrical cables in aircraft. The patented rubber lining means you don’t need to over-tighten for a secure fit.

Release, reseal, and reuse as much as you like without the hassle of cutting and wasting ties after forgetting to run the last wire. Lock and unlock them until you’re done! When you’re ready, flush cut to secure the setup.

You have control over use

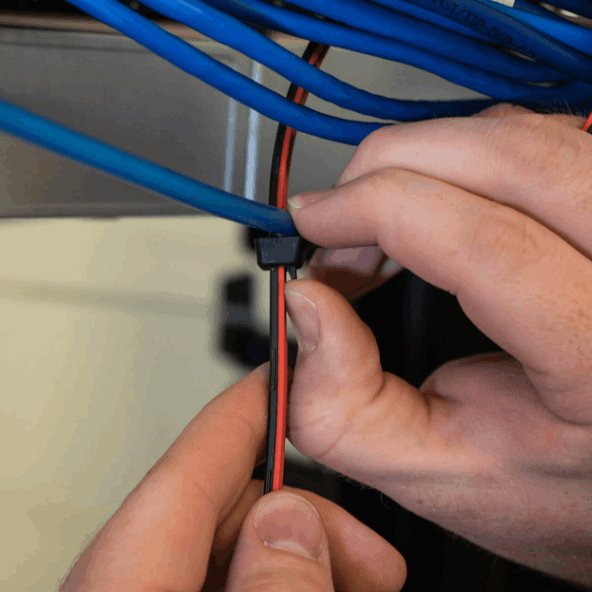

With premium rubber lining, GripLockTies are easily secured. Average zip ties are difficult to keep in place since they’re made of plastic; when plastic rubs against a surface, it slides and shifts around.

GripLockTies do not move and won’t cut wires or scratch off paint on surfaces that may come into contact. Benefit from faster installation and lower costs than separate cushioning materials. The rubber will secure your wires at the exact sizing you need instead of crushing items with the force needed with traditional ties.

They have a rubber lining

The inside of GripLockTies are not made from cheap plastic like a normal zip tie; normal ties have sharp nylon edges that damage anything within reach.

Ultra-protective GripLockTies provide cushioning to bundles that stop wire and cable damage. No other cable can solve the problems of wire and vibration damage. The rubber lining is a true game changer, especially in environments with elevated temperatures and increased movement.

If you would like to learn more, have a read of the versatility of GripLockTies, a comprehensive guide!

The rubber padding is available in several top colours: red, blue and orange. Only the best materials and no questionable quality.

How do you use GripLockTies?

Like a normal zip tie, insert the tail end into the head with the rubber lining on the inside. Pull the tail to tighten as needed; no expensive tool is needed! The deep teeth design produces a satisfying click from the extra-tough-looking head.

If you are not ready to finish the installation or want to add more later on, use the release tab with your thumb to easily open GripLockTies.

After tightening, you can cut off the excess strap and the releasable tab so that it’s flush with the retention head. Feel free to keep it a bit longer to keep the releasable tab in place, it’s completely up to you how you use it to your liking. You don’t have to pull it tight like zip ties; GripLockTies rubber lining removes the stress concentration points under tension, making the tightness stronger for a longer life.

What Are Traditional Zip Ties?

Traditional zip ties (also called cable ties) are simple fastening devices used in multiple industries. They consist of a flexible nylon strap with a ratcheting mechanism that locks the tie in place once tightened.

The design of traditional zip ties is straightforward in comparison to GripLockTies:

- They have a nylon strap. A flexible strip that can be tightened around cables or components. Standard ties are normally made from nylon grade 6.6.

- The ratchet locking mechanism holds the tie in place once the preferred tightness is achieved.

- The tail end (or free end) is pulled through the locking mechanism to secure the tie.

Why should you upgrade from zip ties to GripLockTies?

Standard zip ties are useful, but once tightened, they are not reusable, can damage delicate wires, slip or move during vibrations, and often need a cutting tool to remove them. GripLockTies improve on these issues and are perfect for sensitive wiring projects such as drones, cars, or AV setups. GripLockTies:

- Are great for more difficult installations such as industrial MRO and OEM situations, including high vibration and stationary production, electrical cabinets, lawn and garden, UTV Motos and ATVs, RV, marine, aircraft, heavy equipment, and trailers.

- Rounded edges on the top of the tie also protect insulation, so you don’t need to stress about sharp edges.

- Can be installed in ready-for-use areas where the environment requires heat stabilised and UV protection.

Although zip ties are good for routing wires along surfaces, can be screwed or adhesive mounted, and keep cables off hot or moving parts, they can:

- Fail over time, especially due to moisture or heat.

- Always requires two components: the mount and the zip tie.

- Still uses a regular zip tie, so you cannot reuse it (and are bound to spend more money on supplies).

GripLockTies are a smarter alternative as they eliminate the need for a mount altogether, which is an excellent addition if you’re bundling cables around tubing or bars, securing wires in tight areas where a mount won’t fit, and managing wiring in areas prone to vibration where adhesives won’t hold.

Why are GripLockTies so versatile in applications?

- In aerospace, they secure wiring and components in aircraft.

- For the military, GripLockTies bundle cables in military vehicles and equipment, securing the fastening of wiring and components.

- For technology and data centres, GripLockTies help organise and secure cables.

- In industrial sectors, GripLockTies organise cables and hoses in factories or machinery, reducing clutter and supporting safety.

- GripLockTies maintain performance in harsh outdoor environments (such as exposure to seawater or temperature drops or spikes).

What are the industry applications of standard zip ties?

- In manufacturing and industrial settings, traditional zip ties are used for bundling cables, hoses, and other components.

- In the automotive industry, zip ties are used for securing wiring and components; a simple method for assembly and maintenance.

- With ease of use and availability, zip ties are popular for household and DIY projects, giving homeowners a solution for a range of tasks.

Both GripLock Ties and traditional zip ties have their place in cable management and fastening applications, but the choice between the two depends on reusability, environmental conditions, and cost considerations. AFT can support you with quality products and competitive products to a cross-section of industries and markets.

Looking for GripLockTies? Call AFT Today

Registered and AS9120 quality-certified in 2014, AFT was founded to supply the aerospace and defence fields with specialised fasteners, tooling, and reliable technical support.

Whether you’re hoping to order GripLockTies, Motorsport Fasteners, Cable Tie Mounts, AN, MS and NAS Hardware, Eddie Bolt Tools, Drilling Equipment, or Clecos and Temporary Fasteners, it is easy to get a quote!

As a leader in the fastening system supply chain, we are a company that is quickly emerging and pushing the boundaries of what is possible. We offer a personalised interaction, custom solutions and a value-added service through the product life cycle, from procurement to production, quality, maintenance and repair.

Contact us today for responsiveness, collaboration, flexibility and on-time delivery for fastener and tooling needs. Shop in stock.