Duocel Metal Ceramic Foam – Commercial Applications

- April 16th, 2024

- Categories: Uncategorised

Metal ceramic foam is the backbone of many different manufacturing processes. In fact, foams, sponges, and porous materials with macroscopic pores are critical to various industries and are even used in the construction of aircraft and spaceships!

Why are metal ceramic foams in such high demand? Lightweight cellular materials have always been an important element in the field of aerospace engineering, particularly when the aim is also to scale up processes without compromising on structural quality.

From transport to manufacturing and space, we’ll delve into the commercial structural applications of ceramic foam in aerospace, give an overview of these foam structures, and discuss how the properties of metal foams support complex missions both inside and outside the Earth’s atmosphere.

Duocel Metal Ceramic Foam – History and Insights

A foam structure with a network of ligaments that form cells with open pores, Duocel has always stood out from the competition. Manufactured by American company ERG Aerospace since 1967, the metallic foam has individual ligaments that are solid, strong, and reliable, even while its pores are open. This allows fluids to pass through the entirety of the structure. Overall, this foam is a capable solution for high-performance applications with compact, lightweight, and efficient materials.

Although ERG Aerospace is a leading source for metallic foam today, Shinko Wire was a pioneer in the commercial production of metal foams way back in the 1980s, where they added calcium into an aluminium melt and stirred it in the air to produce oxides and raised its viscosity.

In order to create this variation, Shinko WIre’s engineers used a blowing agent powder that was dispersed into the melt by stirring, decomposing into gaseous hydrogen and titanium at the melt temperature. The melt was then foamed inside the crucible or a dedicated mould, cooled into a large block and sliced into plates of desired thickness. This metallic foam process is known as Alphoras, a method that is still successfully used by many companies and research centres.

A secondary approach was invented in the 1990s by both Alcan International Limited (Montreal) and Norsk Hydro (Norway). Here, the approach was to prepare the melt using ceramic particles–such as silicon carbide or aluminium oxides ranging from 5 to 20% volume–which increases the melt’s viscosity and stabilises the liquid cell walls. Air bubbles were then injected and dispersed into the melt using rotating impellers, resulting in bubbles that were collected into a liquid foam to solidify.

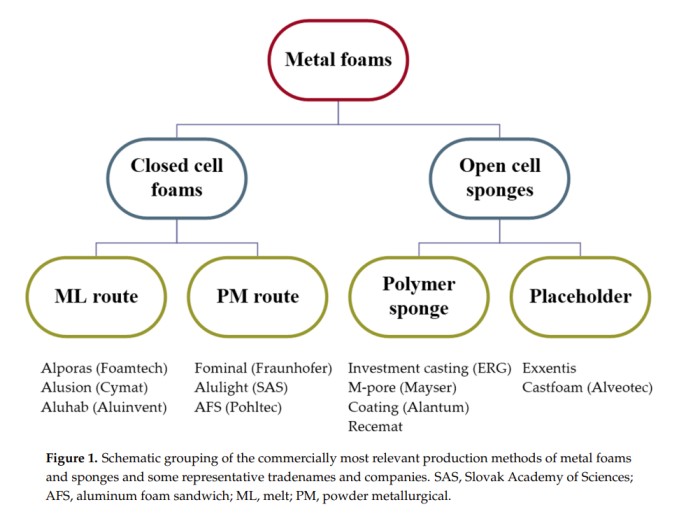

Other production methods include the Powder Metallurgical Route, a process based on Polymer Sponge Structure and the Dissolution of a Placeholder, such as casting moulds filled with granules.

Brief Overview of Commercial Applications

The properties of metal foams have several functional applications and are not just limited to aircraft. From titanium foams, stainless steels, closed cell foams, aluminium foams and their complex geometry, they can be used in the chemical industry, automotive industry, and more. Let’s explore their many exciting uses.

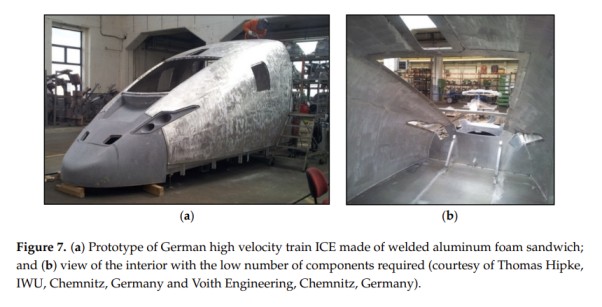

- Metallic foams are used by Foamtech for sound absorption in metro tunnels, in the railway, and on the tunnel and station walls. This supports high air pressure changes and vibrations and is non-flammable. For example, aerodynamic noise reduction prototypes include the pantographs for the Shinkansen train in Japan.

- Duocel aluminium foam has been used as the main component in satellite cryogenic tanks to provide uniform heating and cooling, and space-based infrared optics with solid cryogenic coolers use Duocel as an isothermaliser and baffle structure.

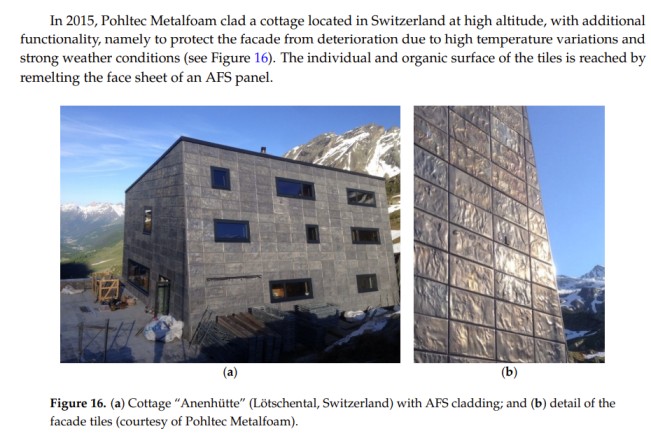

- Pohltec Metalform used heat dissipation on AFS panels by hot forming covered by a ceramic plasma coating as barbeque and cooking plates. This is a convenient, uniform distribution of temperature.

- Due to high temperatures, chemical resistance, and sound absorption, open-cell ceramic foams from Atlantum have been used as silencers, mufflers, diesel particulate filters, selective catalytic reduction, and offering filters for the filtration of gases and liquids, flow control, diffusion, sparging, fluidising, venting, and wicking.

- ERG materials work as heat exchangers from Duocel, able to thermally stabilise the lens of electron scanning microscopes or thermal energy absorbers for medical laser applications. Likewise, the breather plug used in the Lockheed Martin F-22 fighter aircraft for pressure releases during fast altitude changes is protected by Duocel electromagnetic shielding and moisture-wicking properties.

- The ERG heat exchanger made of AI foam was used as heat exchange media and a support matrix of granulated chemicals with multiple layers of amine-based filter, ultimately removing the carbon dioxide and moisture in the space shuttle. Duocel is now used at the International Space Station.

- Alulight used AI-alloy foam panels to protect concrete against flames in burning homes, dissipating heat over large surfaces due to the metal’s high melting temperature and thermal conductivity.

The organic cellular structure is a unique, attractive surface for architectural design purposes. Appealing to metallic foam producers, the solid foam promises great benefits. Likewise, if you want to know more insights, have a read through honeycomb inserts and their role in aviation.

Cellular Structure of Duocel Metal Ceramic Foam

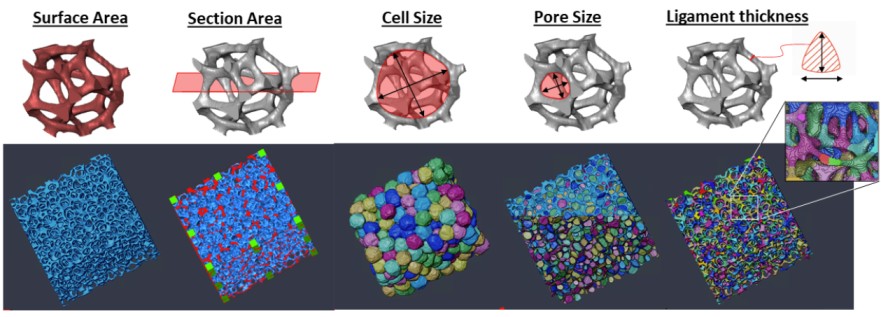

In terms of density, the mechanical properties of metal-ceramic foam rely on the quality of the cellular structure in the sense of cell connectivity, cell roundness, a fraction of the solid contained in cell nodes, diameter distribution, or the cell faces. The larger the ligament cross-section relevant density- the stronger the foam structure, and Duocel’s cross-section can vary.

Open-celled metal foam design. Forming cells with open pores, Duocel is customisable to meet a range of performance requirements. A custom set of properties can be delivered beginning at the base of the material of the foam structure, the pore size, and the relative density.

The foam structure is usually described as isotropic. However, the number of cells must always be larger than 10 for engineers to consider the foam for commercial applications.

Mechanical Properties of Duocel Metal Ceramic Foam

Duocel metal foams’ properties are unique and related to matrix metals. Similar to bulk metals, the mechanical properties of metal-ceramic foam can be improved by hardening mechanisms such as alloy composition, grain refinements, heat treatments, and more. With this in mind, what other properties are important?

Compressive strength

Able to resist fatigue under compression or tensile load, metal ceramic foam can withstand loads without structural degradation.

Acoustic dampening

Due to the cellular structure, acoustic and vibration dampening over a large frequency range is possible. The same property is present in Duocel metallic foams, which provide additional electromagnetic shielding due to their metallic nature.

Malleable

Like a bone structure with dense skin and a lighter core, this foam’s mechanical properties are lightweight and can bend stiffness and energy absorption, exploited in many applications. If you want to learn more about metal foams, read about the importance of ERG materials in advancing aerospace technology.

Thermal Properties of Duocel Metal Ceramic Foam

What are the thermal properties of metal-ceramic foams, and why are they so useful? This strong foam does more than regulate heat.

Thermal insulation

Foams, in general, are known for thermal insulation properties- such as ceramic, glass, and polymeric foams- and are a basis for thermal control. With a large surface area, open-cell metal sponges can be used for passive cooling and heat dissipation. Often, these foams are used as heat exchangers.

Thermal conductivity

As metals are known to be good electrical conductors, combining a large sponge surface allows electrodes in batteries to be utilised for other electrochemical purposes. Duocel is known for its bulk thermal conductivity.

Convective film coefficients

With a mostly triangular cross-section and a short ligament geometry, Duocel offers an advantage to convective cooling. Duocel eliminates or delays the transition from nucleate boiling to film boiling, improving heat transfer due to high local film coefficients.

Energy-absorption

Metal foams can absorb maximum mechanical energy from plastic, irreversible deformation, or a large strain range without exceeding stress limits. For example, isotropic properties are excellent crash absorbers.

Are you a mechanical engineer looking for reliable fasteners or tooling options? At AFT, we provide solutions that add value and through-life support, including supplying and distributing aircraft repair tools, Click Bond fasteners, MS Fasteners, aircraft cable routing systems, and more to match your industry.

Applied Fasteners and Tooling – Duocel Metal Ceramic Foam

If you’ve been looking for Duocel foams, Applied Fasteners and Tooling are industry leaders in supporting new products developed for use in carbon fibre and composite structures for hundreds of applications.

Committed to maintaining a high standard of service as distributors of fasteners and tools for the Aerospace, Military, Defence, Space, Marine, Industrial, Mining, Transport, and Motorsport markets, we adhere to the AS9120 Quality System. Whatever your end goal, we always ensure supplier performance, on-time delivery, and excellent quality.

Whether you’re looking for marine-bonded fasteners, GripLockTies, honeycomb inserts, or ceramic foam for an architectural build, we prepare you for the task ahead.

Contact us today for a competitive quote on cable drum dispensers, motorsport fasteners, Avibank Ball Lok Pins, cable tie mounts, or anything you need for your next metal ceramic foam project!