Top 5 Benefits of Using Quick Release Pins in Marine Applications

- February 10th, 2025

- Categories: Uncategorised

If you are an engineer in the marine industry and often work with naval ships, ball lock pins have many safety applications you need to know about. Also called pip pins or safety pins, ball lock or quick-release pins are used in place of nuts and bolts when frequent or quick assembly is required.

This blog will guide you to the benefits of these pins, their applications, and why they are non-negotiable in the defence sectors.

For both maintenance and manufacturing activities for all aerospace and defence customers, it is essential to rely on timely fastener and tooling products. So, how can you decide what will work best with your project?

What Are Quick Release Pins?

Quick Release pins are quick-release fasteners used in aerospace, electronic production, manufacturing, robotics, and automotive industries. They are a type of alignment pin used to join and fasten components with a single button.

Quick Release pins involve a pin and a locking mechanism at one end (often a set of spring-loaded balls). When activated, spring mechanisms draw the balls inside the pin shaft, locking the pin into place.

When a push button is released, the spring-loaded ball is reactivated, retracting the balls and allowing the pins to be removed without multiple steps!

Able to handle high levels of stress, wear, and corrosion, some of the materials and finishes used in ball lok pins include:

- Alloy steel Strong and durable, alloy steel ball lok pins are suitable for heavy duty applications that demand impact resistance and high shear strength. Although it is more vulnerable to corrosion than stainless steel, it has a higher tensile strength and hardness.

- Stainless steel These ball lok pins are good for environments exposed to chemicals, moisture, and other corrosive elements. Long-lasting in harsh conditions, this material is commonly used in the marine industry.

- Manganese phosphate finish Applied to alloy steel ball lok pins to improve wear resistance and corrosion protection by creating a porous surface that reduces friction between moving parts. Alloy steel extends the life of the pin and enhances resistance to seizing and galling.

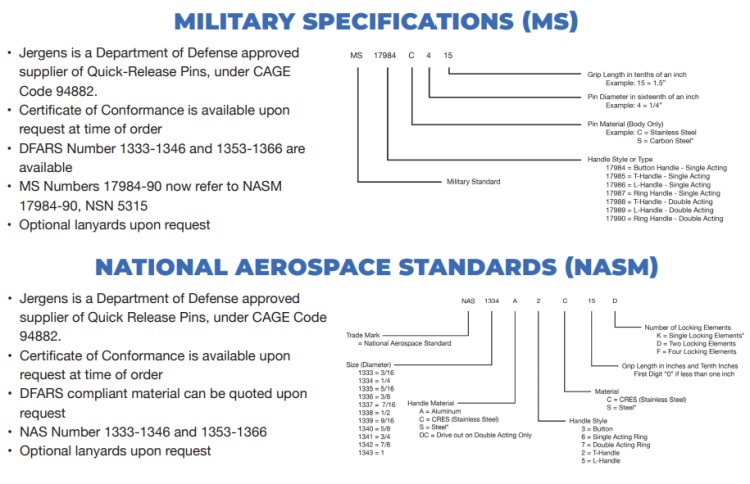

In any case, you want MS-certified or NAS-certified ball lok pins designed to meet military specifications for durability.

Different Types of Quick Release Pins

There are two types of ball lock pins which are categorised by their operating mechanism: double-acting and single-acting. Each is used for a wide range of applications. Let’s take a look at the types engineers can consider:

Single-acting ball lok pins

Are you working in an environment where time efficiency and ease of use is a priority? With these lok pins, the locking balls are spring loaded, so they automatically engage when the pin is inserted into a hole. Button or handle-operated, single-acting pins are ideal for one-handed, quick-operations when only the release mechanism must be activated to unlock the pin.

These pins are also used in applications where fast and secure engagement is non-negotiable, but the pin doesn’t need manual locking.

Double-acting ball lok pins

Will accidental locking or unlocking be a problem for your project? If you’re working with heavy components, these pins offer more control as they require both the removal and inserts of the pin to be manually engaged. The locking balls are positive locking until released by pushing or pulling the centre spindle attached to the pin body handle.

Pulling on the handle releases the balls and removes the pin in a single motion. Overall, double-acting pins provide greater security and precision for projects. It will not lock unless intentionally engaged.

Lifting pins

Heavy duty and designed to help in the safe fitting of heavy loads, this includes a single piece body and positive locking until released by pushing the button on top of the shaft.

Lifting pins allow for secure, quick attachment to a high-tension load, facilitating easy moving or lifting without complex rigging.

What about ball lok pins used in the marine industry?

Also known as ball locking and ball detent pins, quick-release pins simplify the process of assembling and disassembling parts and are available in different styles, including marine.

Although quick-release pins look similar to others, they are characterised by a superior level of corrosion resistance. What are some of the components featured in marine-style quick-release pins?

- The head

- The body

- The pair of spring-loaded locking balls

- The button or ring

Installing marine quick release pins involve the locking balls receding into the body. The locking balls will pop right out once in the locking position, securing the parts together. Pushing the button on the top of the head will disengage the locking balls so you can remove the pins.

What is the difference between marine and traditional quick-release pins? Traditional pins are designed for a wider scope of environments, while marine pins are specifically for humid or wet environments where corrosion is a concern.

The majority of marine quick-release pins are made of 300 series stainless steel, whereas traditional pins are made of aluminium or carbon steel to withstand corrosion from seawater.

Precisely designed to strict specifications to prevent failure, quick-release pins are used in yachts, boats, and aircraft.

If you’d like more insight, have a read of Avibank ball lok pins in military and aerospace applications! pins in military and aerospace applications

Ball Lok Pins in Marine Applications: The Benefits

Whether you’re working on a large ship, boat, or submarine, these pins offer many advantages for the marine field. From access covers to frames that need to be moved at a moment’s notice, why are they so critical to safety?

Secure and Quick Fastening

Quick release pins for the marine field are used to secure various panels, doors, and hatches on navy ships. With the quick-release mechanism, engineers can experience a fast removal and reassembly, such as during maintenance or emergency situations.

For example, on navy ships, Quick release pins are used to secure deck fittings (such as davits, cleats, and winches), can be easily inserted and removed, and is overall quick when attaching equipment such as rafts or small boats.

Supporting a tool-free operation, the personnel can perform tasks quickly, saving time for critical operations or when making repairs in confined spaces.

Safety Security for Personnel

Pins are used for safety devices such as ladders, guardrails, and other personal safety personnel.

The pins ultimately offer an easy way to secure temporary safety barriers or rigging equipment, especially when mobility is needed during drills or deployment.

Quick release pins contribute to safety and operational efficiency, making sure that equipment (such as firefighting gear or emergency lighting) is firmly in place when needed and can be adjusted or removed without risk to personnel.

For example, fire extinguishers and emergency escape equipment can be attached to a ship’s framework using pins.

Connecting Tactical and Communication Equipment

Tactical gear such as communication arrays, antennas, and other sensitive equipment is mounted using pins. These maintain operational effectiveness on naval vessels by supporting the rapid deployment and adjustment of communication systems and antennas.

For example, if navy personnel are stuck in harsh weather conditions at sea, ball lok pins make sure that communication equipment stays in place yet can be repositioned or removed.

These pins are also employed for securing tactical equipment during combat, such as weapons storage compartments, armored doors, or heavy-duty barricades.

Reliable in Harsh Marine Environments

Quick release pins are resistant to corrosion and wear, so they are ideal for use in harsh saltwater and high-moisture conditions aboard navy ships. They are often constructed from stainless steel or other corrosion-resistant materials so they stay functional.

These pins maintain their strength and reliability even when exposed to the corrosive effects of saltwater, remaining intact in the toughest conditions.

Safety in Maintenance and Repairs

When engineers perform maintenance or repairs on navy vessels, pins can be used to secure scaffolding, access points, and temporary walkways.

This easy release ensures that supports can be adjusted or removed quickly as personnel move around the ship. Access to critical areas is flexible and safe, reducing the risk of injuries or accidents.

Jergens Kwik-Lok Marine Pins: An Overview

If you’re on the hunt for the most corrosive resistant pin for marine environments, let’s dive into Jergens Kwik-Lok Release Pins for marine applications. As a U.S. manufacturer of stainless steel Kwik-Lok pins, spring plungers, threaded inserts, dowel pins, hoist rings, work holding tooling components and mounting systems, Jergens has provided engineering solutions for over 80 years.

- The Recessed Button Handle Marine Pin helps prevent accidental actuation of the pin

- The Ring-Handle Marine Pin is designed for applications that require a small clearance around the pin

- The Heavy Duty Detent Pin provides a high pull-out force with its heavy-duty spring and locking balls

- The Marine Pin’s Stainless Steel can handle tough environmental conditions

What about the materials of the pin body? Thankfully, all the components are durable.

- The handle is made from 300 Series Stainless Steel

- The button material is 300 Series Stainless Steel

- The Recessed & Ring Handle is 17-4 PH Stainless Steel

- The Heavy Duty Detent is a 300 Series Stainless Steel

- The spindle is 17-4PH Stainless Steel

- The spring and balls are 300 Series Stainless Steel

Jergens is an ISO 9001:2015 and AS9100 certified, government QSL-approved manufacturer, and AFT offers a quick turnaround for special grip length, materials, and ball configurations.

Ball Lok Pin Fasteners: Shop in Stock!

Supplying and supporting quality fasteners and assembly tooling to aerospace, space, defence platforms and industrial programs worldwide, AFT was registered and AS9120 quality certified in 2014. Emerging as a leader in the fastening system supply chain, we always push the boundaries of what is possible.

Whether you’re looking for honeycomb inserts, cable drum dispensers, aircraft cable management systems, motorsport fasteners, hi lok fasteners, Click Bond fasteners, cable tie mounts, speciality fasteners, we have a wide range you can shop in stock.

Visit our showroom in Docklands or contact us at support@aft.systems get a quote!