A Guide To Using Temporary Fasteners

- June 13th, 2024

- Categories: Uncategorised

According to a recent market report, the global automotive fasteners market size is projected to grow from $24.08 billion in 2024 to $37.11 billion by 2023.

Whether you’re working on an aircraft or a naval ship, you must know what fasteners will work best with each project. While permanent fasteners (such as weld nuts and rivets) are designed to have a more secure, long-lasting bond, nuts, bolts, screws, and washers are all examples of temporary fasteners that bond for a shorter period.

Let’s explore the importance of temporary fasteners, the types available, and how you can engineer them in your projects.

Cleco Fasteners: A Specialised Temporary Fastener

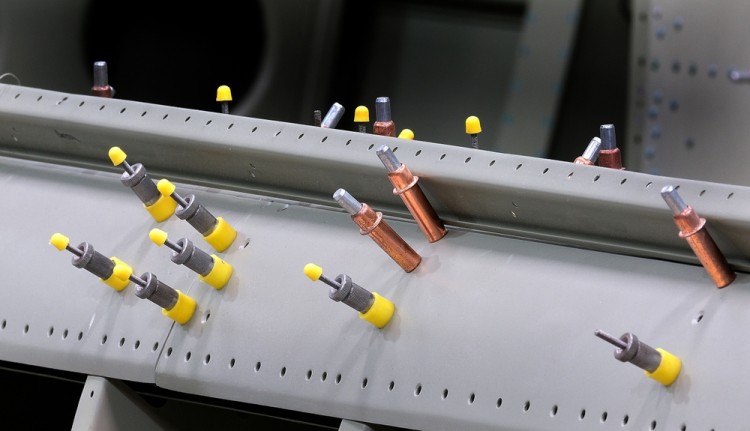

Developed by the Cleveland Pneumatic Tool Company–now known as Cleco Tools– Cleco type fasteners are used in the manufacture and repair of aluminium aircrafts, where they help to fasten sheets of metal together until they are permanently joined.

Designed for use in holes in aerospace applications, Cleco fasteners come in many shapes and sizes. They hold sheet metal parts together to support alignment during welding and other assembly. Cleco fasteners include heavy-duty Clecos, miniatures, hex nuts, wing nuts, long hex nuts, long wing nuts, and side-grip clamps.

How do Cleco fasteners work? Its cylindrical body includes a spring, and a plunger connects to this spring on the end. A special handheld tool is then used to install them and engage the spring-loaded plunger. After the fastener is positioned over the hole, the Cleco locking jaws will enter the hole.

When compared to other hardware options, Cleco offers tight tolerance and ease of assembly and guarantees high-quality sheet metal fabrication. With this in mind, what else does this temporary fastener offer that others do not?

It is precise

When drilling holes in strategic locations, Cleco fasteners can be inserted to hold parts in place until they are permanently joined.

Instead of stabilising parts with a vice grip to reach high tolerances, Cleco gives engineers peace of mind that none of the parts will move during the welding process.. Aeroplanes often feature sheet metal panels, and Cleco fasteners can be used to hold these sheet metal panels together.

It is efficient

Applying Clecos and Temporary Fasteners ensures that you’re not wasting time building jigs for a tighter tolerance or asking team members to hold parts still.

Engineers can expect a higher-quality assembly when you drill holes, insert Cleco fasteners, and complete the joining. For example, a laser can cut Cleco holes in an asymmetrical pattern, making them easier to find.

It is reusable

Cleco fasteners aren’t a one-time tool. In fact, they are designed to be used multiple times. When replacing a Cleco fastener with a more permanent type, there’s no need to discard it. Instead, the Cleco fastener can be reused for other temporary fastener applications in the future.

Different types

There are many Cleco temporary fasteners for a range of applications. Operated with special tools, plier-based Clecos are quick to install and remove, making them ideal for fast-paced environments.

Wing-nut Clecos are manually tightened and ideal for thicker materials or where substantial clamping force is needed. Additionally, side-grip Clecos clamp the edge of workpieces or where holes aren’t available for standard Clecos.

In high-tolerance applications, cylindrical-bodied temporary fasteners clamp with more tension and support the hole from damage. There are also new types made to the hole size, which has a large backside footprint to stop any backside damage, especially in composites.

Save money and time

If you’ve ever needed to get parts remade due to the assembly not being right the first time, engineers don’t need to worry about Clecos.

Cleco fasteners are renowned for providing a well-aligned, tight fit, which can save you valuable time and money. Consider using a welding alternative such as rivets to assemble parts.

Why use Cleco Temporary Fasteners?

What materials are you working with, and what are the requirements for your project? Let’s look at some of the ways you can use Cleco temporary fasteners.

Heavy-duty applications. Working with thicker or tougher materials? Wing-nut Clecos offer a clamping force for a firm grip.

Standard sheet metal assembly. Plier-operated Clecos are fast to apply, secure to hold, and can be used to assess aircraft fuselages or automotive body panels.

At the edge of materials or tight spaces, side-grip Clecos are excellent where traditional Clecos won’t fit or when holes aren’t a fastening option.

For fast assembly or disassembly. If you need to move quickly without compromising security or precision, plier-operated Clecos are invaluable tools.

Kwik-Lok Temporary Fasteners

Kwik-Lok offers a high-clamp load and torque control for various aerospace applications as a complete line of temporary fasteners.

Kwik-Lok has a diverse collection of high-quality, precise tools such as plier-operated temporary fasteners, power-operated and manual fasteners, power nut runners and drill stops, side grips and clamps. Let’s look at some different types.

Kwik-Lok K-Type Fastener (1/16″ Diameter)

As a standard Kwik-Lol plier-operated fastener, this is a spring-loaded, steel-bodied fastener for most space requirements. It is easy to install and suitable for 25 lbs clamping force and 1/16″ diameter holes.

Kwik-Lok – KK Type Fastener (3.0mm Diameter)

This is a miniature Kwik-Lok plier-operated fastener, spring-loaded, steel-bodied, and a shorter overall body length. It is designed for more confined areas that prevent the use of a standard K-type fastener. Ideal for 3.0mm diameter holes and has a 0.6-5 mm grip range.

Kwik-Lok – KL Type Fastener (3/16″ Diameter)

Pillar-operated and steel bodies, the Kwik-Lok KL-type has an extended grip of 1/4-1/2″. Spring-loaded and steel-bodied, it is easy to install and suited for a maximum of 25 lbs of clamping force. A longer grip is essential for thicker applications.

Kwik-Lok – KHNS-Type Fastener (1/8″ Diameter)

Power-operated with a free-wheeling design, this Kwik-Lok KHNS short-grip hex nut fastener works with high-production applications that need a consistent, uniform clamping force.

This fastener, which is pneumatic-driven with the Power NutRunner KNR2000, is a time saver suited for both metallic and composite materials. It also has a shorter grip range for thinner applications.

Types of General Fasteners

Temporary fasteners join two materials or objects, seamlessly able to be removed and reused without damaging the objects they hold together. What are the common types of fasteners?

Nuts

When combined with a bolt, nuts assemble multiple components. Shear nuts, lock nuts, wing nuts, and hexagonal nuts are commonly used with bolts to clamp two materials together. By creating friction, hexagonal nuts keep objects sturdy.

Lock nuts will lock without using an object for friction and will be used in various assemblies across aerospace industries.

Finally, wing nuts are ideal for temporary assemblies that require frequent removal. The head of the nut has a wing shape, making it easy to install and remove manually.

Externally-threaded

Threaded fasteners are one of the most common fastener types, and they are used in projects across many industries. Bolts, screws, and studs are identified with their external thread profile.

Bolts are often used with nuts (sometimes a washer) for long-lasting but temporary fastening, and they are uninstalled and reinstalled as needed. Tightening the nut on the bolt created friction, holding the fastener in place with a clamp load.

Working similar to a bolt, screws make use of an internally-threaded hole. Machine screws, self-tapping screws and grub screws are temporary fasteners that can be uninstalled. As for studs, they don’t have a head, are threaded on each side, and join two materials through the internal threads on each component.

It’s important to remember that threaded fasteners can be prone to breakage or loosening from high cyclic loadings such as vibrations.

Washers

Washers are often used with a bolt and nut. They maximise the bearing area in an assembly, provide more torque, and protect the fastened object. Flat washers are the most common, evenly distributed load during tightening.

Likewise, repair washes are similar to flat washers yet have a bigger diameter. The load is spread wider, greatly reducing the chances of object damage.

Spring washers offer a locking mechanism, stopping a bolt from being prone to vibrations or cyclic loading. A spring-loaded design can handle more pressure than a flat washer.

Cup washes have a curved design and are mainly used in assemblies that involve wood. The head of a bolt or screw can fit into this design for a flush finish.

Rivets

As a more permanent fastening solution that cannot be moved without the risk of damaging materials, it’s critical to use them correctly. Rivets join larger, flatter materials such as metal sheeting or plates.

With a solid shaft and head on one side, solid rivets are the most common. It is deformed using a rivet gun to create a solid fastening.

Pop rivets – or blind rivets – are used in metal fixing applications where the assembly ‘blind side’ is limited. The body and the mandrel can be put through a drilled hole and fixed into place.

Likewise, similar to solid rivets, tubular rivets have a hollowed-out shaft that is used in commercial applications. Aircraft maintenance often also has to cold form the holes to prestress them. If you would like to learn more, have a read of cold-working fasteners and tooling and how they support defence applications.

Applied Fasteners and Tooling – Reliable Aircraft Tools

Are you assembling a custom aluminium frame for a high-performance racing car? Precision and alignment are essential for aerodynamics, and Applied Fasteners and Tooling are reputable AS9120 quality-certified suppliers of mission-critical components. Whether you need motorsport fasteners, honeycomb inserts, Countersink Tooling, Click Bond fasteners or Hi-Lok fasteners, we have everything you need for your project outcome.

With stringent product quality testing, repair and maintenance support, and application engineering support, we provide solutions that add value for defence, aerospace, transport, energy, and many heavy-duty markets.

Contact us today for through-life support services.