Quick Guide to Selecting the Right Aircraft Repair Tools for Your Needs

- August 05th, 2024

- Categories: Uncategorised

Thousands of flights take off daily, and when they do, passenger and crew safety is paramount. When it comes to aviation engineering, the building blocks of these aircraft must be highly regulated and meet stringent quality standards without fail. After all, it only takes one incident or event to damage lives and cause commercial damage.

For example, the Civil Aviation Authority has standards in place that outline that UK airlines have a Tool and Accountability policy that outlines tools and equipment, tool control, and tool labelling. Similar standards apply to the U.S., as outlined in the Federal Aviation Administrator. Regardless of the location, aerospace engineers need to exceed these standards when using basic or specialised equipment.

Effective tool management is critical in ensuring safety, regulatory compliance and operational efficiency, and Aerospace engineers need to exceed these standards when using basic or specialised equipment. This article is your best guide to the necessary tools for aircraft maintenance, repair, and overhaul.

Types of Aircraft Repair Tools

Airlines go to extraordinary lengths for pre-flight security checks , and these measures are to make sure the aircraft is as safe as possible. A similar process also takes place for outer-space missions with spacecraft. With this in mind, let’s explore the most common–and essential–tools you cannot go without for routine servicing.

Basic Aerospace Tools

Basic hand tools are essential for every aircraft mechanic, and it’s important to invest in tools that are durable, comfortable to use, and can get the job done to a high standard. From Hand Tools to simple high-speed steel Drill Bits, Lighting Hole Punches and Sealant Guns, let’s take a look at some of the most common hand tools used in aviation.

Screwdrivers

Including both Phillips head (numbers one and two) and flat head, screwdrivers are essential for removing and tightening screws and fasteners of different sizes for various aircraft components.

For example, padded handles can degrade or react with aviation chemicals, so choose hard plastic in this case. Incorrect sizes can cause wear and tear and require more manual labour.

Pliers

Slip-joint pliers, duckbill, diagonal, needle-nose pliers, and locking pliers are indispensable for bending, gripping, and manipulating objects.

Across the board, pliers are essential for jobs that involve twisting, bending, and shaping, such as safety wires, cables, and other small parts.

Punches

These allow mechanics to create holes in sheet metal, as well as find the centre of a circle, drill holes, or remove damaged rivets or bolts.

Available in hollow or standard types, punches create these holes without dinting the metal, transferring holes from paper to metal and creating an ideal opening for screws.

Wrenches

Open-end, box-end, adjustable wrenches are necessary for loosening and tightening nuts, fittings, and bolts throughout an aircraft.

For example, a torque wrench requires a specific level of torque and is calibrated by the user with the gauge attached. Once a screw has the ideal toque level, the wrench will click and alert the operator to remove the wrench.

Impact driver

Designed to loosen stuck fasteners, an impact driver is struck with a mallet or hammer to remove corroded bits or overly-torqued screws. These drivers provide a level of force that is unachievable by a regular handheld screwdriver.

Magnets

Small magnetic parts can become a hazard if they enter moving equipment during a flight. Long and expendable, magnets can access hard-to-reach places and collect fragmented pieces, keeping them away from wiring or the engine.

Rivet guns

Driving a rivet through the metal, a rivet gun creates a joint and fastens pieces together. Placing bolts and screws where the mechanic cannot access the back of the material, riveting is sturdy and lightweight for many applications.

Aviation maintenance toolkit

A well-organised, sturdy toolbox has compartments and dividers to keep tools easily accessible and within reach when you need it. A rolling toolbox is an excellent idea if you do a lot of field work.

Although these machine tools are useful in any toolbox, in more complex aerospace applications, you may need a more specialised tool for the job to prevent costly repairs.

Specialised Aerospace Tools

Let’s take a look at some specialised, proper tools you might use for maintenance procedures and routine inspections.

Countersink Tooling

If your aerospace industry project requires thin sheet metal and composite material stack-ups, countersink tooling such as carbide, high-speed steel, or diamond is essential.

As a cone-shaped cutting tool used for deburring, countersinking drill holes, countersinking screws, countersinking ensures that fasteners (like rivets or screws) sit flush with the surface of the material, preventing protrusions that can cause aerodynamic disturbances or weaken the material.

The tool creates a tapered surface at the mouth of the hole, enlarging the top part of the hole to the required diameter and angle. You can cut conical holes for flathead screws using countersink types such as general types, micro stops, and piloted cutters with two or three flutes.

NutPlate Drill Jigs

Nutplates are self-wrenching, self-locking nuts used in constrained areas to offer a permanent nut element inside a joint. These quality tools allow an access panel fairing or another element to be attached with a screw, and nut plate drill jigs accurately locate and drill rivet holes for nut plate anchors.

Drilling jigs are used to ream, drill, and tap to perform other operations and boring jigs boreholes that are either too large to drill or are odd in size.

Cherry Tooling

Cherry Aerospace has provided aerospace installation tools to aircraft manufacturers and repair facilities worldwide for over 60 years, and Cherry Tooling is CE-certified. For example, hand-tooling and pneumatic units for aerospace blind fasteners or the Cherry range such as CherryMAX and CherryLock.

CherryLok blind rivets are locked spindle flush fracturing structural rivets with various sizes, strength levels, and materials. They are ideal for sealing applications and joints needing a sheet take-up. CherryMAX, on the other hand, is used for thin-sheet applications and materials damaged by blind rivets.

JIFFY Tooling

Offering market-leading solutions (such as hand-held, limited access, and pneumatic drilling) for 80 years, JIFFY Air Tools created the “Modular Tool” platform for drill motors and attachments, from drilling units to nut runners.

Aerospace demands high performance, and all gears in JIFFY air tool drill attachments include C-Type 18% nickel tool steel (C-350) with a tensile strength of 350 ksi or 350,000 pounds per square inch.

JIFFY offers torque control tools, installation tools, customised removal kits, lube-free tools, protective covers, and drilling tools.

Helicoil Tooling

Also known as a Helicoil insert or a screw thread insert, Helicoil tooling includes a stainless steel wire with a diamond-shaped cross-section. It repairs stripped thread in hard metals like steel or soft materials such as plastic or wood.

Overall, they allow for screws to be inserted without damaging native threads on a part, and Helicoils can easily be replaced if they begin to wear from corrosion, damage, or strip.

The advantages of Helicoil tooling are the thread size range (as small as #2 and as large as 1 1/2″ diameter), its thread type configurations (UNC, UNF, Metric Coarse Pitch and Fine Pitch, UNEF, UNS, and Pipe Thread) and material options, from stainless steel to titanium.

Aerospace Fasteners

Along with tooling, let’s look at some of the fasteners you can use.

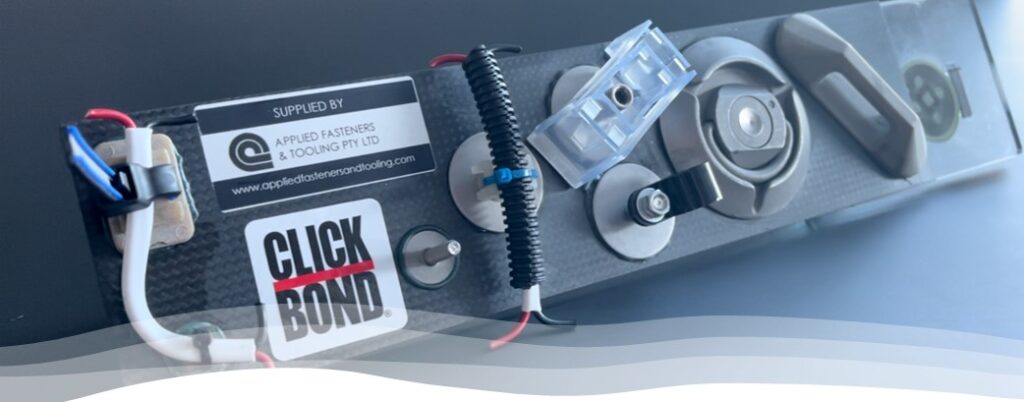

Click Bond

Popular and widely applicable to military aviation and commercial aviation, Click Bond offers bonded fastening solutions.

Cable Tie Mounts, rivetless nut plates, standoffs, studs, sleeves, brackets, and advanced composite threaded fasteners support aerospace manufacturers with adhesive-bonded fastener technology. This improves structural characteristics, extends product life and streamlines the manufacturing process.

For example, rivetless nutplates eliminate the need for drilling attachment rivet holes once used for nutplate installation. This preserves the structural integrity, longevity, supports weight savings, and reduces installation, rework, repair time, and overall expenses.

Hi-Lok Fasteners

As a trademark of the Hi-Shear Corporation, Hi-Lok fasteners are the industry standard for high-strength and permanent airframe fasteners. Compared to traditional bolt and nut systems, Hi-Lok fasteners don’t add weight to aircraft.

Combining the best features of a rivet and a bolt created a lightweight fastener with a one-sided installation. You can design more with less, delivering high fatigue resistance without compromising on strength.

If you would like to learn more, look at our guide to using temporary fasteners and learn how you can engineer them for your projects!

Avibank Fasteners

Avibank Ball Lok Pins are made by Avibank, a world-leading manufacturer that specialises in designing and producing multi-component fastening systems.

For example, Ball Lok Pins join and fasten aircraft components and workpieces ground support equipment components, provide an adjustable grip length, and require the press of a button to be unlocked.

These pins are often available in steel or stainless steel, and knowing how to measure the Ball Lok Pin you require is important. Measure the diameter of the metal pin, and measure the length from the bottom of the handle to the ball of the pin.

Applied Fasteners and Tooling: Aircraft Tools

Do you need reliable aircraft repair tools or aerospace fasteners that meet Approved Standards? Applied Fasteners and Tooling was registered and AS9120 quality certified in 2014. It was founded to supply the aerospace and defence industries with specialised fastening products and technical support.

Whether you need Cable Tie Mounts, Grip Lock Ties, Hi-Lok Tooling, Marine Bonded Fasteners, pneumatic tools, tightening tools, rivet removal tools, socket wrenches, combination wrenches, safety wire pliers, or something more specific, we are an industry leader you can rely on for fasteners and tooling needs.

Contact us today for Quality Assurance Procurement Requirements and support through product life cycle, procurement, production, quality, maintenance, and repair.