The Importance of Precision in Nutplate Tooling for Aerospace Assemblies

- March 07th, 2025

- Categories: Uncategorised

Do you need to secure the structural elements of an aircraft? In aerospace manufacturing, it’s the smallest (yet mighty) of components that play a critical role in the integrity and reliability of the final product.

Precision in nutplate tooling and installation is indispensable to ensure safety, reliability, and compliance with stringent aerospace standards.

In this blog, we delve into the significance of nutplates, their features, installation processes, and why engineers consider them non-negotiable.

What Are Nutplates?

Also called anchor nuts, nutplates by Click Bond incorporate a floating nut design for easy alignment and replacement of the nut element. There’s no need to rework the installation’s location. If you work with aerospace fastener applications that require high cycle attachment points on an aircraft, nutplates do an excellent job.

Nutplates provide a durable, secure attachment point in aerospace assemblies. These components are often installed in hard-to-reach areas where conventional nuts and bolts cannot be used.

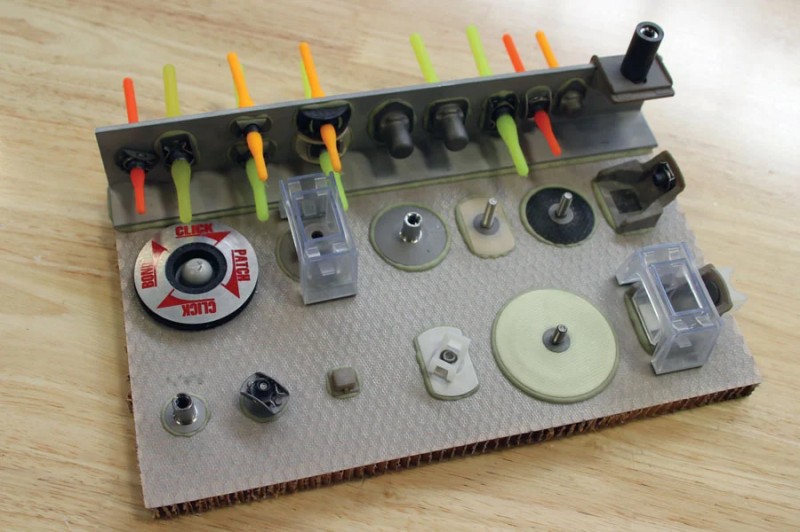

Disposable installation fixtures are also included with every nutplate, a proprietary technology that centres the nutplate on the fastening hole. Some of the applications for nutplates include:

- Decking and floorboards

- Equipment and attachment

- Fairing

- Fuel and fluid tanks

- Interior

- Panels

- Pressurised Vessels

- Systems attachment

Primary Features of Nutplates

- Self-locking Mechanism Nutplates often feature a self-locking system, which ensures that the fasteners remain secure even under intense vibrations and stresses.

- Compact Design Their slim profile allows them to fit in confined spaces, making them ideal for complex aerospace assemblies.

- Corrosion Resistance Made from high-grade materials like stainless steel or titanium, nutplates are designed to withstand extreme environmental conditions.

- Ease of Maintenance Nutplates simplify maintenance by allowing bolts to be removed and reinstalled without compromising the integrity of the assembly.

CB6005 – No Lug Sealed Nutplate

This is a sealed, no-lug nutplate for the closeout of wet bays or pressure vessels with reduced footprint requirements.

The fixture makes nutplate installation easier with a bond line clamp-up and maintenance of concentricity with the fastener hole. The CB6005 ensures full availability of nut floats for the protection of threads from the adhesive. Materials are A-286 Stainless Steel.

CB6003 – No-Lug Clip-Retained Nutplate

This no-lug nutplate includes a reliable clip-retained nut element suitable for general applications.

An integral elastic installation fixture simplifies nutplate installation with the bond line clamp-up. This ensures full availability of nut float and protection of threads from adhesive. The standard baseplate is A-286 Stainless Steel, and the nut retention clip is 302 Stainless Steel or ARMCO 18-2 MN Stainless Steel.

CB6008 – One-Lug Sealed Nutplate

The one-lug nutplate is ideal for wet bays or pressure vessels with reduced footprint needs. It is supplied with an integral elastic installation fixture. Materials include A286 Stainless Steel.

Types of Nutplates

Nutplates come in various designs, such as:

Floating Nutplates: Used in the aerospace, aircraft, electronics and defence industries, these allow for slight misalignment during installation. Low-profile, lightweight plates are used to install a captive nut behind a panel.

Floating nutplates are made from carbon steel, iron alloy and corrosion-resistant steel, with cadmium plate, silver, and dry lubricant as the finish.

Fixed Nutplates: Designed for blind-mounted applications where you can’t use hex nuts (or where it’s desirable to have an attached nut), fixed nutplates make maintenance easy. Materials include carbon steel and alloy steel with a cadmium plate finish.

High-Strength Nutplates: Great for weight reduction, improved strength, and structural integrity that lowers assembly costs. High-strength nutplates are as low as 1/5th the weight of conventional anchor plates, have a higher proof load, free-flowing characteristics for self-alignment with a bolt, self-retention features, and are pre-taped so you don’t need expensive thread-cutting screws.

Installation Processes for Nutplates

Proper installation of nutplates is as critical as their design. Here is a quick installation guide by Click Bond:

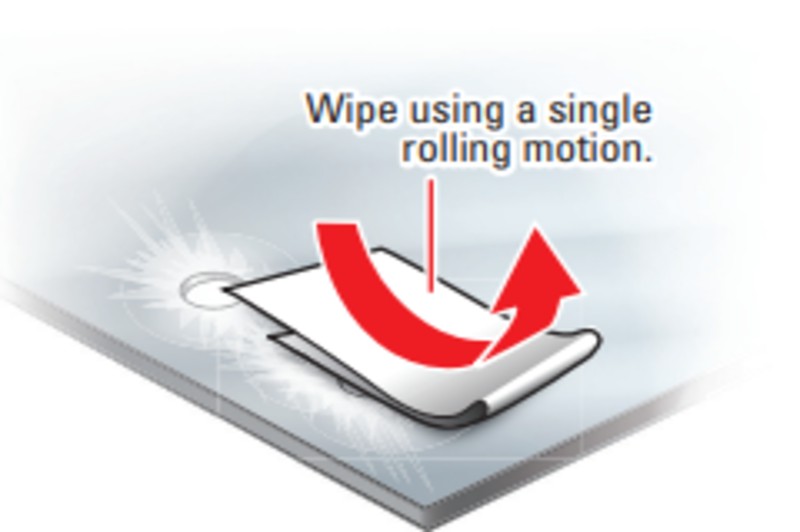

Step 1 Prepare the substrate and remove all surface contaminants with a clean, lint-free cloth and fresh cleaning solvent (CB911 or acetone), saturating the cloth with the solvent and wiping the substrate with a single rolling motion. Always use the clean side of the cloth for each wipe.

Step 2 Prepare the part. Solvent wipes the nutplate base with a single rolling motion to remove residue. Unprimed parts should be abraded prior to solvent wipe.

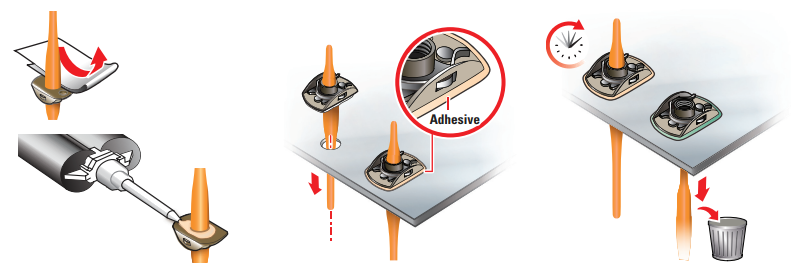

Step 3 Locate and bond. Align the nutplate and use the installation fixture to gently pull the nutplate into place. Take care not to pull too hard on the installation fixture.

Step 4 Cure and complete. Allow the adhesive to cure. Do not wipe away adhesive squeeze out, and do not disturb part of the fixture during the cure. If necessary, touch up the coatings!

What tools should you use for installation?

- Drill and countersink tools are used to prepare the installation surface.

- Rivet guns or screws for securing nutplates.

- Torque wrenches for precise tightening.

- Alignment jigs to ensure proper positioning.

Whether you need Cable Tie Mounts, Motorsport Fasteners, Specialty Fasteners, Hi Lok Tooling, Countersink Tooling, Spares, or Drilling Equipment, AFT supplies what your project needs at Approved Standards.

Regulatory Compliance and Testing Standards

Aerospace is one of the most regulated industries. Compliance with standards like AS9100 ensures quality and reliability in aerospace components.

Nutplates must meet specific requirements outlined in regulatory frameworks such as FAA and EASA guidelines.

At AFT, all external providers manufacturing/fabricating components to our PO requirements shall ensure they are certified by an IAQG-approved certifying body to AS9100, and a First Article inspection is performed as per AS9012 + AFT additional requirements. All external service providers acting as non-value-added distributors with AS9100 certification must have a Scope of Approval that includes Distribution if AS9120 certification is not held.

For an in-depth look, read our Quality Assurance Procurement Requirements. Why is this compliance so important?

- Safety Assurance Compliance means nutplates meet strength and durability criteria.

- Certification Requirements Aircraft components must pass testing to achieve airworthiness certification. Applied Fasteners and Tooling have years of experience making sure supplies are aerospace-worthy.

- Quality Control Regulatory standards drive continuous improvement in manufacturing processes.

Applied Fasteners and Tooling is registered and AS9120 quality certified (2014) and was founded to supply the aerospace and defence industries with specialised fastening products and technical support.

Aerospace Tooling: Contact Applied Fasteners and Tooling!

Committed to supplying top-quality products at competitive prices to a cross-section of markets (from space to marine, aerospace, and electrical to transport), AFT is a reliable partner known for exceptional quality and delivery for all fastener and tooling needs.

Emerging as a leader in the fastening system supply chain and working closely with innovative fastener technologies, we offer a personalised interaction and value-added service. Working with the design, procurement, production, quality, maintenance, and repair, our customers depend on us as partners known for our collaboration, flexibility, and responsiveness.

Contact us today by emailing support@aft.systems or call +61 3 8080 0763 to Shop in Stock or Request a Quote! After all, we aim to push the boundaries of what is possible.