The Science Behind Radar Absorption Materials

- April 17th, 2024

- Categories: Uncategorised

Radar Absorption Materials or ‘RAMs’ are incredibly important to defence and security departments across the world. These materials are utilised for a wide variety of military and civilian applications, such as reducing the radar signature for aircraft, ships, tanks, and other mobile objects, EM interference shielding, human exposure mitigation, or reducing reflected radiation from microstrip radiators.

The lining materials of EMC anechoic are designed to absorb radio waves and microwave energies; this is commonly known as radar absorption materials (RAM), and is essential for the functioning of security and defence of our region.

Today, we are going to delve deep into the science behind radar absorption materials. We’ll cover everything from the importance of this stealthy technology to its basic principles, common materials, and how RAMs are critical to aerospace, defence platforms, and industrial programs worldwide.

Definitions of Radar-Absorbing Materials

The application of the absorbers requires weight reduction for energy efficiency and operation capability at a broad bandwidth.

Relevant for a reduction in signatures for deception and detection in several military systems, carbonaceous particles are promising for many future applications that involve the development of sustainable, environmentally friendly, high-strength-to-ratio, and mechanically flexible materials.

Since the performance of all types of anechoic lining declines as the angle of the waves deviates from 90 degrees, these chambers must be large.

Composite Materials for Radar Absorption

Polymer composites comprise a carbonaceous material filled into a polymer matrix, offering flexibility in complex design due to the embedding of rubbers, thermoplastics, C black, CNT, carbon fibre, CNF graphene, or graphene oxide. As well as military purposes, radar absorption materials are important to the commercial field as well! Let’s explore more on the materials that support electromagnetic compatibility.

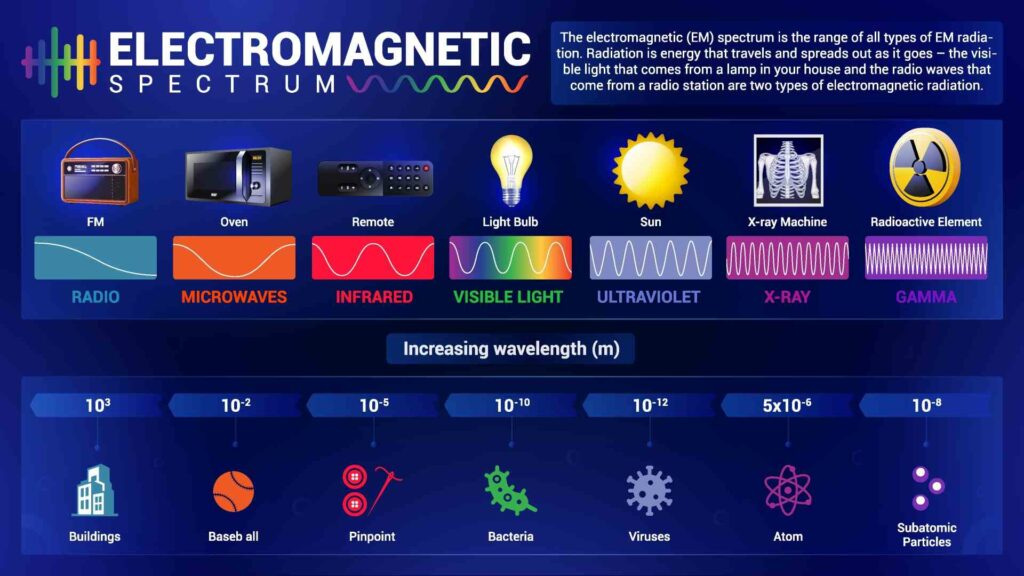

By blending conductive carbon black with the binder matrix of glass/epoxy composite, the radar absorbing structure (RAS) is able to support loads and an X-Band of 8.2-12GHz and frequency ranges centred at 10GHz. With this in mind, what are the main materials that contribute to their potential applications?

Layered structures

As many radar-absorbing composites use layered structures with alternating layers of dielectric or conductive materials, this design helps to maximise absorption across a range of frequencies.

Carbon-based material

Carbon fibres or carbon nanotubes are often used in radar absorption composites due to their high electrical conductivity and ability to absorb electromagnetic waves. Ferrite materials. These composites are also used for radar absorption as they have magnetic properties that absorb and dissipate electromagnetic waves.

Design considerations

The thickness, arrangement of layers, types of materials, and specific radar frequencies need to be considered for effective absorption.

Importance of Radar-absorbing Materials in Stealth Technology

Radar absorption materials play a part in protecting bases from being located and uncovering military tasks from the enemy, supporting the security of military bases, comfortable work environments, performing military duties, and a range of military applications.

Google Earth and satellite access make it easier to identify security threats, so regional security and secrecy need to be handled to protect national defence. With the use of Radar Absorption Material from GF/PPS laminated composite materials, this can be placed on the infrastructure of military bases, working as an effective disguise for strategic areas from using a Google Earth radar.

Absorption properties are also useful to the Royal Australia Navy, tested for peel and tear, and can reduce the range of which other sea or airborne platforms can detect submarines. Absorbers are consistently validated through measurements performed by electronic warfare and radar experts.

The age of RAMs is also of critical importance. This was noted back in 2012 within a report released by the Department of Defence. According to their findings, older radar absorption materials show evidence of rust and deterioration, while newer radar absorption materials do not need to rely on hydrofluoric acid treatment (an extremely hazardous substance!).

Basic Principles of Radar Absorption

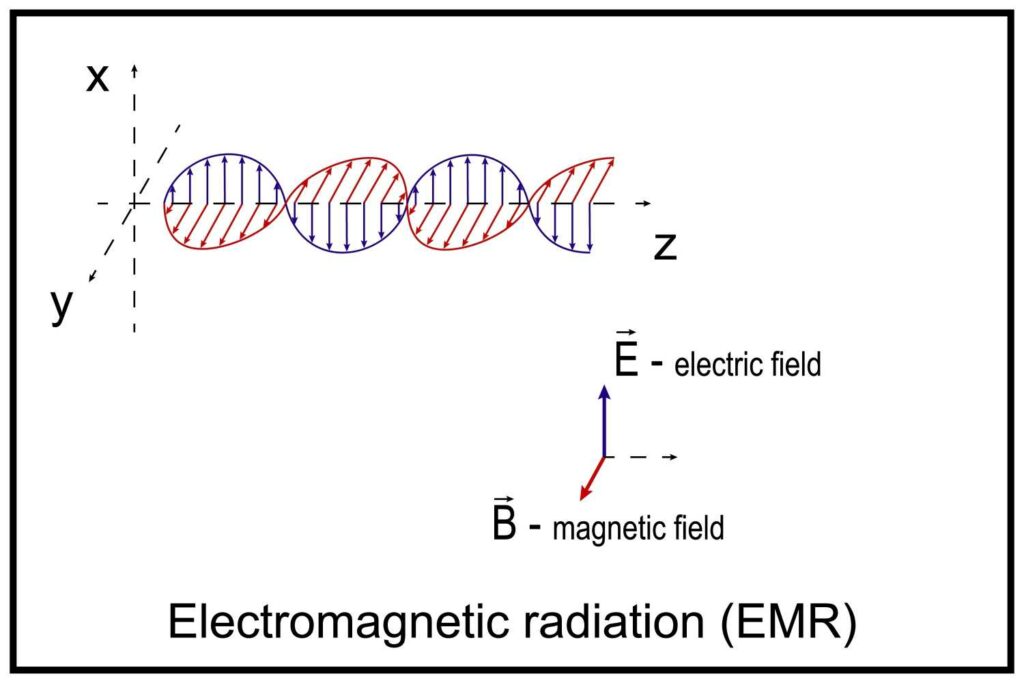

Although radar absorption doesn’t use sound waves but short-term microwaves, the principle of radar is identical to sound. When it comes to contact with an object, these waves reverberate so the distance to a target and its direction can be accurately calculated. This information is then put into the form of digital data on a screen so it is readable.

The wave passes through its environment in a straight line, reflected when it hits an object in its path, then returns to its original position, known as reflection. For example, using a special gear, a marine scanner rotates 360 degrees from its vertical access. As the direction of the antenna is clear when the radio energy is transmitted, the bearing of targets in the path of this beam of energy is understood. The sharper the beam, the more accurate this is.

For example, in the maritime field, the analysis of this echo makes it possible to obtain excess information by calculation and logistical deductions, such as whether an object is moving, approaching, or stationary. With this in mind, what are some common principles for radar absorption?

- Permittivity and permeability. The EM propagation depends on the electric field’s permittivity and the magnetic field’s permeability.

- Measurement techniques such as the T/R Method. A sample is placed into a waveguide or coaxial cable, which works well for medium or high-loss materials. It’s important to be aware of “air gaps”, and it is difficult to work above 10 GHz.

- Free Space Method. This involves both transmission and reflection methods, de-embedding, and measuring non-uniform materials, works best with high frequencies, and diffractions at the corners can appear.

Are you looking for high-performance practical applications for electromagnetic wave testing? AFT prioritises critical industries that rely on the full traceability of their products. From motorsport fasteners to GripLockTies, Hi Lok Fasteners and Avibank Ball Lok Pin essentials, our parts are supplied with a certificate of conformance to your requirements.

Materials Used in Radar Absorption

RAM can be made from two different types of materials; however, both are commonly used in different areas of the same chamber.

- Closed-cell polyurethane or polystyrene foam is moulded into a steep pyramid shape, dosed with carbon, and then painted with fire-resistant paint. Mimicking free space, this absorbs the radio or microwave through a resistive structure that has a larger shape, making the wave energy convert into heat.

- Made with 100mmx100mmx6mm thickness, ferrite tiles have a central fixing hole. Made from sintered iron/nickel material, this is ground to a precise shape so large wall sections can be assembled without intertile gaps. Being the same density as steel, the chamber support frame and roof structure need to be attached to a backing layer. With magnetic permeability, they operate well at lower frequencies.

- Hybrid linings and mixed-cell linings enhance the performance of ferrite tiles. They are modified by placing a wedge or pyramid-shaped absorbers in front of them. With hybrid linings, the chamber must operate at frequencies above 1000MHz.

Want to understand more about fasteners and tooling that could benefit your next project? Have a look at exploring the uses of cable tie mounts.

Anechoic Chambers and Testing

Anechoic chambers are shielded rooms that absorb the reflections of electromagnetic radiation, but what are these chambers, and why are they critical for radiofrequency testing?

- Radar-Absorption-Material (RAM) is applied to the walls, ceiling, and floor, providing a layout for radio frequency signal absorption across the required frequency band to produce the quiet zone. This zone is the volume in which the antenna is placed and where the electromagnetic reflections are a minimum.

- As table-top-sized enclosures or often room-sized where engineers can walk in to work, these rooms minimise interfering energy disturbances from external sources.

- As we can’t see radio waves directly, these must be measured by radio receivers and antennas. Anechoic chambers measure the antenna’s performance under testing, which helps engineers with gain and pattern characteristics.

- This chamber wall construction is a Faraday cage, which prevents external signals from entering the anechoic chamber and interference with measurements, stopping test signals from escaping and becoming a health risk.

- The inside surface is often pyramidal, giving the room a unique look. This approach has been very beneficial to antenna testing, or Vector Network Analyser (VNA). If a low-power measurement is to be taken, use the VNA as the transmit power source and the receiver measurement system. The radio frequency transmits a signal produced in the VNA and can be routed via coaxial cables to a transmit standard gain horn. If a higher power source is needed, additional amplifiers may be required in the radio frequency path.

- Likewise, a positioning system is required in the anechoic chamber to hold and move the antenna concerning the incoming plane wave, determining the antenna’s spatial radiation pattern.

Overall, all support structures and fitting used inside EMC structures must be made from non-conductive materials with low dielectric factors, such as modern polymers. Although not ideal, wood has been used due to its low cost. If you’d like to learn more about radar absorption, check out the critical role of EMI/RFI shielding for military defence.

Applied Fasteners and Tooling – Radar Absorbing Material Suppliers

Applied Fasteners and Tooling is an industry leader in the fastening system supply chain, working closely with only the best, innovative technologies and companies that push the boundaries of what is possible.

Whether you’re aiming to complete radar signal testing, understand electromagnetic properties and frequency range, or are looking for reliable stealth technology for your next mission, we have a wide range of industry-approved fasteners and tooling to expedite your job markets.

As military fastener suppliers that supply and support quality assembly tooling consumables for aerospace, space, defence platforms, and industrial programs worldwide, we understand electromagnetic radiation and always meet the Quality Assurance Procurement Requirements.

Registered and AS9120 quality certified in 2014, contact us today for personalised interaction, technical support, maintenance, repair, and on-time delivery.