Applications of Click-Loc Systems in Next-Generation Aerospace Designs

- February 17th, 2025

- Categories: Uncategorised

Whether it’s a spacecraft launch or a commercial aeroplane, aerospace industries require foolproof critical systems. The evolution of aerospace technology means challenges in safety, efficiency, and performance, and Click-Loc self-locking systems offer reliability and simplicity when fastening.

This blog will be your ultimate guide to Click-Loc systems and why they are essential for the aviation industry. Let’s explore the applications, benefits, and future potential of Click-Loc systems in next-generation aerospace designs! Safety is non-negotiable when it comes to any aircraft project.

Applications of Click-Loc Systems in Aerospace Design

Let’s look at the amazing applications of Click-Loc systems in aerospace!

1. Commercial Aviation

- Fuselage and Wing Structures Click-Loc fasteners join critical structures like fuselage panels.

- Interior Applications From securing seats to overhead bins, Click-Loc systems make for easy reconfiguration during design updates or repairs.

- Engine Components Able to handle intense vibrations, Click-Loc is indispensable for fastening engine cowlings and mounts.

2. Military and Defence

- High-Performance Aircraft Lightweight yet strong, Click-Loc fasteners enhance the agility and durability of fighter jets.

- Unmanned Aerial Vehicles (UAVs) Click-Loc systems secure lightweight payloads and sensors.

- Missiles and Spacecraft Components remain intact during launch and deployment.

3. Space Exploration

- Launch Vehicles Click-Loc systems contribute to structural integrity under the intense forces of liftoff.

- Spacecraft Modules They secure solar panels and payloads to help spacecraft function in space.

- Habitat Modules Easy installation and removal make these fasteners ideal for modular construction in space stations.

What are some real-world examples of the genius of Click-Loc?

- NASA’s Artemis Program Click-Loc systems were used to lock down critical payload components, reducing assembly time.

- Commercial Jetliner Upgrades Retrofitting older aircraft with Click-Loc fasteners resulted in weight reductions, saving thousands of litres of fuel annually.

- Military UAVs Increased payload capacity and reduced vibrations allowed for sophisticated surveillance equipment.

With applications spanning aviation, defence, and space exploration, Click-Loc is a pioneer and market leader in self-locking technology.

Understanding Click-Loc Systems

Fast, reliable, and reusable, Click-Loc systems are advanced self-locking fasteners that keep aerospace components in place. Powered by Moeller Aerospace, they use an integrated locking mechanism, so there’s no need for external devices like washers or adhesives. Click-Loc systems perform well under high vibration, temperature fluctuations, and extreme conditions. Let’s look at some of the benefits!

- Custom-designed and patented self-locking technology

- 100% positive-locking mechanism resists loosening from vibration, stress, extreme thermal cycling, and other environmental conditions

- An alternative to lockwire, tab washers, cotter pins, deformed threads, thread-locking compounds, and locking elements

- Specified for Flight Safety-Critical Applications

What are the top ten characteristics of Click-Loc Systems?

- Patented technology

- Custom-designed solutions

- High reusability

- Temperature-resistant

- Lower-product lifecycle costs

- Easy to use

- FOD adverse

- Mistake proof

- Improve product reliability and maintainability

- Reduced product maintenance downtime

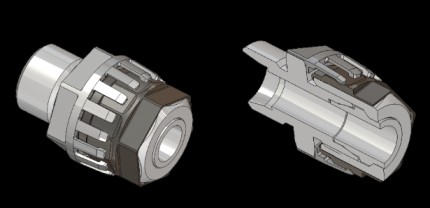

Self-Locking Fittings

- Provides a secondary locking solution for fuel, fluid and gas couplings and nuts made from titanium, steel and nickel alloys to stop unintended back-off due to vibration, stress, or thermal conditions

- Low complexity, easy to install, error-proof and can be used to replace sharp, FOD-prone backwire

- Cuts maintenance downtime and risk of system failure

- Customised to work with a range of industrial applications

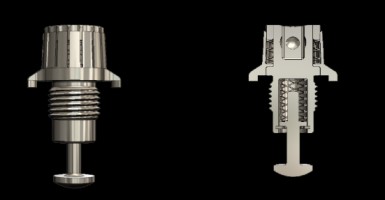

Self-Locking Plugs

Click-Loc Self-Locking Plugs provide a strong secondary locking solution to protect and cover access and inspection ports of borescope, drain, and sensor applications within gas turbine engines. They also:

- Replace tedious, time-consuming lock ware and safety cables

- Reduce maintenance downtime and lower the product lifecycle cost

- Have been tested to achieve hundreds of assembly and disassembly cycles without failure

- Take seconds to install, requiring no special training, tools, or secondary actions

- Are made from Inocel material

- Operate in temperatures over 600 degrees Celsius

- Include fully-customisable sizes

Self-locking fasteners originated in industries requiring high reliability, but it was the aerospace sector that drove their refinement.

Click-Loc systems have since evolved with materials like high-strength alloys and composites, meeting the demands of modern aerospace engineering.

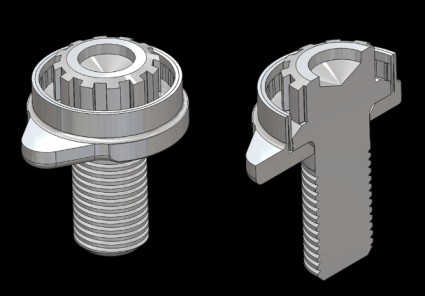

Self-Locking Fasteners

- Inconel material

- Operating temperatures of up to 600 degrees Celsius

- Customisable sizes

- Prevents unintended back off of nut and bolt applications in harsh environments, high vibration, and hard-to-reach areas

- Self-contained and FOD adverse with no removable parts

- A 100% positive locking mechanism will never loosen

- Applications include turnbuckle fasteners, washer cup assemblies, nut and bolt assemblies, bolt and washer assemblies, bearing lock nuts, pylon locks, retaining nuts, lockrings, adjustable rock ends, helm joints, hydraulic connectors, and rod-end adjusters.

Types and Classifications

What are the different types and classifications of Click-Loc systems? These vary depending on their applications:

- Threaded Fasteners Ideal for structural assemblies.

- Quick-Release Systems Designed for easier maintenance.

- Custom Fasteners Recommended for specific environments, such as space exploration.

Going through a precision manufacturing process (such as CNC machining and advanced surface treatments) ensures that Click-Loc fasteners meet aerospace quality standards.

Advantages of Click-Loc Systems in Aerospace Applications

Why do Click-Loc systems have unlimited possibilities in aerospace?

1. Lightweight Design

Is your aerospace project weight-sensitive? Evenly distributing load, Click-Loc systems are lighter than traditional fasteners, supporting fuel efficiency and payload capacity.

Made from titanium and high-grade aluminium alloys, Click-Loc minimises weight while still being high-strength. For example, their use in fuselage assemblies can shave kilograms off an aircraft’s total weight.

You don’t need extra locking components (such as washers, locking tabs, or safety wires) due to the self-locking feature of Click-Loc!

2. Compliant with Quality Standards

- Being AS9100/ISO9001/ISO14001 certified and NADCAP approved, Click-Loc fasteners excel in high-stress environments. They are able to secure engine components during supersonic flight and can maintain structural integrity under extreme forces.

- NAPCAP is accredited for chemical processing dry film (Wixom only), non-conventional machining (EDM), and nondestructive testing FPI (Wixom only).

- Compliant with GE-S-1000, PW QA-6076, and MIL-Q09858A

- REACH is compliant and does not contain any SVHCs. Safety-critical applications stay protected.

3. Simplified Installation and Removal

Unlike traditional systems needing multiple components, Click-Loc fasteners are easy to install and remove, streamlining manufacturing and maintenance processes.

The design is also interchangeable, with self-locking drop-in replacement plugs that can be used to replace or dual source an existing plug if the mating port is already designed. Retrofit fluid fitting can be designed for existing fluid fittings.

4. Resistance to Vibration and Shock

The aerospace environment subjects components to relentless vibration and shock, especially spaceships that exit and enter the Earth’s atmosphere.

Inconel 718 has a higher tensile strength than stainless steel 304 and is the main material of Click-Loc products. A nickel-chromium-based superalloy, Inconel can maintain its strength at higher operating temperatures.

These fasteners also contain enough iron to reduce susceptibility to cracking after being welded. Click-Loc systems are engineered to remain secure under these conditions and support reliable connections.

5. Corrosion Resistance

Click-Loc is made from Inconel to handle exposure to varying temperatures, humidity, and other environmental factors.

Inconel has high corrosion, oxidation, and pressure resistance due to its passivation layer, which forms when heated. Nickel (which is an alloy element in Inconel) fights chloride-iron stress corrosion cracking.

If you would like to learn more about Click-Loc, read about the benefits of using Click-Loc self-locking systems in aerospace applications!

Click-Loc Systems: Order from Applied Fasteners and Tooling

Click-Loc Self-Locking Systems are redefining aerospace fastening, and Applied Fasteners and Tooling is an authorised representative of Click-Loc in Australia, New Zealand, and South East Asia.

Registered and AS9120 quality certified in 2014, AFT was founded to supply the aerospace and defence industries with specialist fastening products and technical support. Offering a personalised interaction and value-added service through the product lifestyle, we work with the design, procurement, production, quality, maintenance and repair.

Whether you’re looking for Click Bond, Motorsport Fasteners, Cable Tie Mounts, Hi Lok Tooling, or Countersink Tooling, AFT customers depend on us as a reliable partner known for our responsiveness, collaboration, flexibility, and on-time delivery.

For a comprehensive range of Click-Loc fasteners with full technical support, contact our technical team at +61 3 9939 8979 or support@aft.systems or visit the Click-Loc website. Contact us to Shop in Stock!