Why Use Eddie Bolt Tools for Maintenance and Repairs

- March 19th, 2024

- Categories: Uncategorised

Critical aerospace applications need appropriate tooling to handle extreme conditions in the aerospace industry. The wrong tooling, on the other hand, can have detrimental effects and pose a serious safety risk to all parties involved.

Offering high-performance aerospace fastening, Eddie Bolt tools is one of the most important tools in the industry.

Eddie-bolt pins and nuts are a positive mechanical lock that can be designed with five flutes in the upper portion of the threaded area, while also being available in various materials, diameters, and finishes. As you can see, these tools are both multi-faceted and serve a variety of different purposes. So, why exactly should you use Eddie tools for maintenance and repairs? Keep reading to find out!?

Benefits of Using Eddie Bolt Tools

Why are Eddie Bolt Tools used for custom solutions in aerospace? Let’s explore the benefits of various applications and settings!

Faster installation

As a free-running nut, the Eddie bolt speeds and simplifies installation by allowing the nut to be installed up to the sheet line with no prevailing torque.

Reduced rework

Eddie bolts substantially reduce tool wear and breakage by eliminating the potential for galling at high Eddie bolt installation speeds. This is largely due to the low level of friction that is generated between the pin and nut. In this case, the Spline-Lok Key recess is ideal for torque-reaction capability.

Limited access capability

Able to be used where other systems cannot, Eddie-bolt tooling has a low profile pin and nut. These unique nuts and bolts support installation processes while also making limited-access tooling possible.

High-vibration resistance

This true mechanical lock provides superior vibration resistance in comparison to other fastening systems that rely on friction locks.

Improved joint performance

With a high, consistent clamp-up, Eddie tooling offers excellent static and fatigue strengths that are perfect for heavy-duty applications that rely on strength and durability.

Simplified tooling option

The Eddie-Bolt 2 tooling system can cut out the need for torque-controlled tooling.

Unless otherwise specifically stated on the applicable standard, specification, or other controlling document(such as the customer’s P.O), all Eddie-Nuts may be lubricated, at the manufacturer’s option, with cetyl alcohol per MIL-L-87132, Type I or Type III.

Need to be more sure of the testing and approval process for fasteners and tools? Have a read of aerospace defence testing and approval. Everything you need to know is in one article!

Assembly Tools for Eddie-Bolt System

Offset Pistol Grip Tools

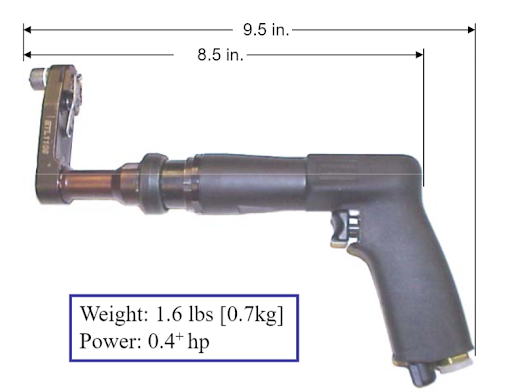

As a new pistol grip motor, this is available in tool models ETL1108, ETL1109, ETL1110, ETL1111, and ETL2000 in diameters -5, -6, and -8 diameters.

Model ET1110 is designed to be used with a flush socket gear up to 08 diameters, and Model ET1108, flush socket gears, are available in 05 and 06 diameters only.

ETL1129

With five gears, the ETL1129 is designed to install -5, -6, and -8 diameter fasteners with extended sockets. This model can flush socket gears on 05 and 06 diameters only.

17-Degree Offset Tools

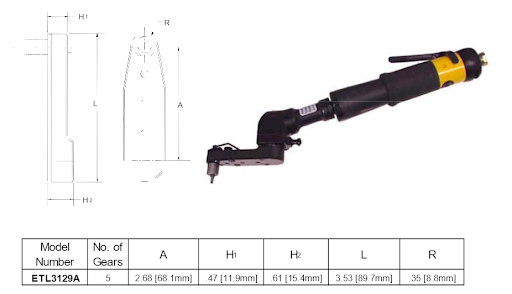

Designed for use with extended sockets on all sizes, Model ETL3129A flush sockets can only be used within the -05 and -06 diameters.

90-Degree Offset Tools

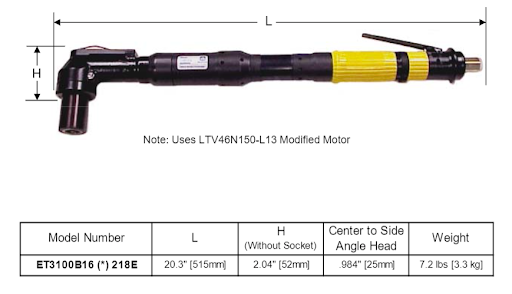

Using an LTV38N68-13 Modified Motor, the ET3100B16 contains a Hex Key size, Extended Socket Length, Fastener Diameter, and Tool Model Number for identification when used for projects.

Accessories for Power Installation Tools

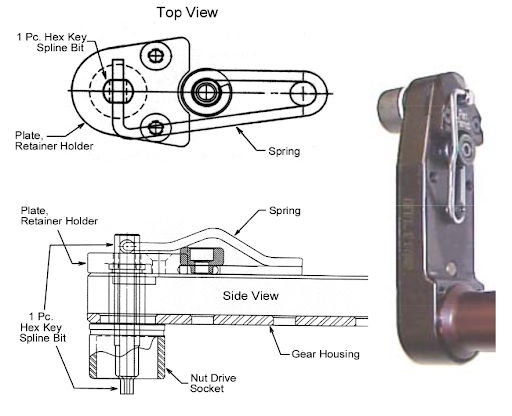

- The “Ergo Key” system is for power tools and converting from the Hex Key to Spline-Lock. This system kit can include a plate, retainer holder, return spring, bearing pins, and all necessary screws and bushings.

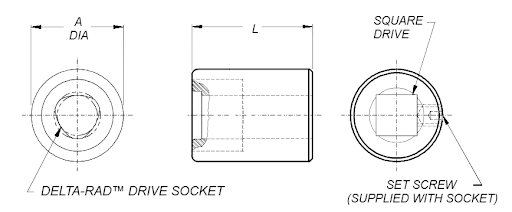

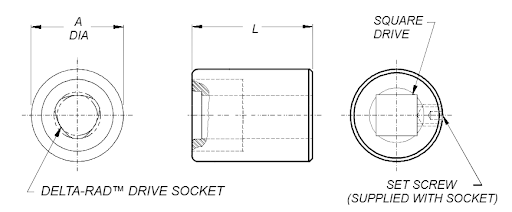

- Extended sockets for power tools. Applications include the Delta-Rad socket insert and the Retaining Ring, which cover a range of tool models.

- Spline-Lok Keys for power tool applications such as Models ETL1108, ETL1110, ETL3110, ETL1117, and more.

- Flush Socket Gears. Socket Gear Part numbers such as 461-9008, 461-9202, and 461-9009 are compatible with many power tool models.

Do you want to learn more about useful tools and fasteners within the Defence industry? Explore the uses of cable tie mounts and how they are essential for heavy-duty applications.

Hand Installation Tools

Hand Ratchet Wrench

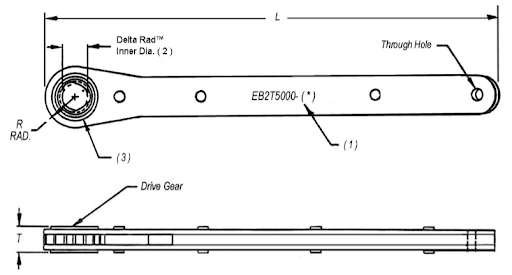

These are identified with Wrench Part Number, Alcoa Fastening Systems, and data of the manufacturer, which doesn’t need to include its location. The Delta Rad Driver is then inspected using the EB2G2000 Gauge. An example of a Complete Wrench Model Number is EB2T5000-6.

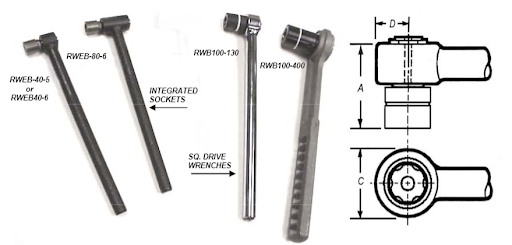

Roller Wrenches

EB2T4020 series sockets are used with RWB100 series roller wrenches, with the Delta-Rad Driver inspected using an EB2G2000 Gauge.

It’s important to note that the nature of this installation of the Eddie-Bolt 2 System results in a large drop in installation torque wrench forces as the Eddie bolt installation is completed. Always exercise care to avoid injury during manual installation due to this drop in resistance.

Hand Sockets

With the Delta-Rad Drive Socket and Set Screw, the material insert is carbide, with the body being alloy steel and heat treated. The finish has no insert with black oxide as the body.

Other tools include the Offset Hand Ratchet Wrench, the Curved Handle Hand Wrench, the Hand Wrench with Pivot Handle, the 45-degree Offset Handle, the Double-ended 45-degree Offset Handle, the Crow Foot Hand Wrench, Spline-Lok Key, Hex Wrenches, and Roller Wrenches.

Spline-Lok Key Wrenches For Eddie-Bolt Applications

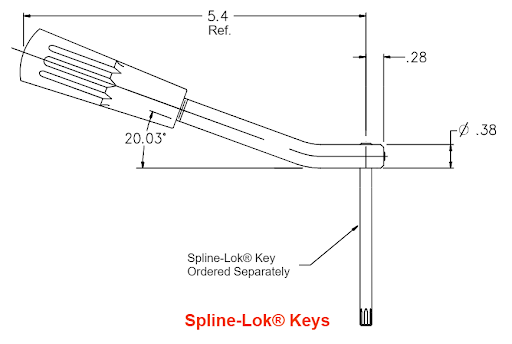

With handle assembly ordered separately, Spline-Lok Keys need to be ordered separately. Limited Access Spline-Lok Keys apply an Alcoa Fastening System; an example of a basic part number is SPK651 and a Spline-Lok bit size.

These keys must be used with hand installation tools only.

Inspection Gauges

Paddle Gauges

This paddle gauge inspects an installed Eddie Nut to ensure it is fully swaged. It is commonly used as a Go/No-Go gauge; if the gauge fits over the installed fastener, it is a “Go”, but if the gauge doesn’t fit, it is considered a “No Go”.

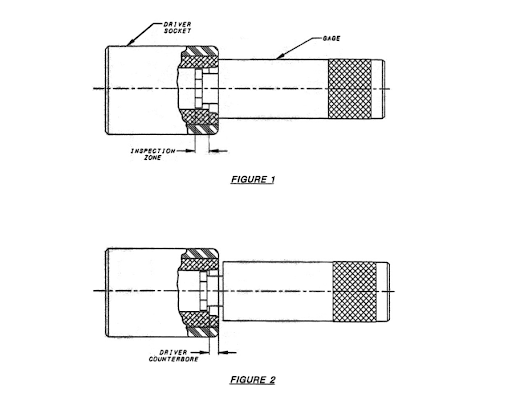

Driver / Socket Inspection Gauge

When the gauge is fully inserted into the driver, it is rotated. While continuing to attempt to rotate, the gauge is moved out toward the driver counterbore.

Master Pin Gauge

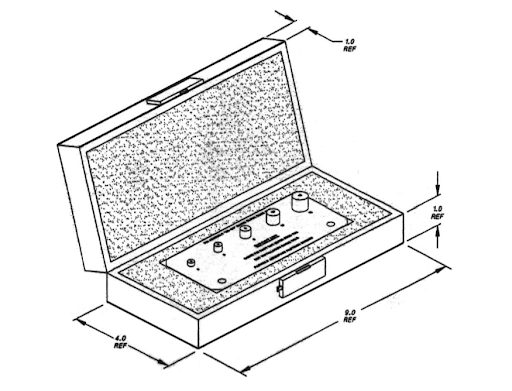

The Master Pin Gauge checks for wear on the Paddle and Cylindrical Nut Inspection Gauges, which are stainless steel and heat-treated. Other gauges include the Pin Protrusion Gauge, which is sold as a set only, and the Grip Gauge For Selection of Proper Grip Length, or “EB2G1400”.

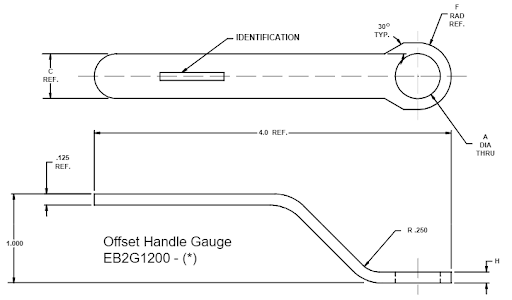

Note: A “New Tool Application Form” allows you to order your desired tool. What you need to include in the “R” Dimension Minimum in Inches; “B” Minimum Clearance over the pin in inches, Diameter of the EN Nut; “A” Maximum and Minimum Offset Dimensions; “H” Maximum Height Dimensions, including Socket Max inches, and if an extended Socket is required for your project.

Eddie Bolt Tools – Installation and Maintenance

Recommended Hole Diameters

- Clearance fit hole diameters are recommended whenever steel, titanium, or composites are in the material stack-up.

- Close ream hole diameters are recommended for net to minimal clearance conditions.

- Transition fit hole diameters are recommended in aluminium structures with a close to slight interference fit.

- Interference fit hole diameters are recommended in aluminium structures. This provides improved load transfer and improved fatigue performance.

Hole Preparation

Round, clean holes within tolerance and with minimal burrs are fundamental for excellent joint performance and durability, but what can achieve the best installation? Here are a few tips and tricks.

- Eddie pins are installed in a wide range of hole diameters.

- Drill/ream sizes should be chosen to generate holes within the diameter ranges shown on drawings, standards, or installation specifications.

- Clamping of the structure with temporary devices helps avoid hole misalignment, sheet separation, burrs, or chips between the sheets.

- Drills should be sharp as this benefits hole quality and productivity and reduces operator fatigue.

- With an aluminium structure, drill speeds of 4000 to 6000 RPM are recommended; stainless steel or titanium requires an RPM of 300 to 1000, and countersink cutters or carbide drills are recommended for composite structures.

- Excess sealing on the threads of the pin can contaminate installation tooling and should be wiped off prior to engaging in the tool.

- Excessive “push” on the drill motor (dull drill) can create sheet separation, burrs, or chips between the sheets. Deburring tools and other consumables can help prevent this!

- Hole normality is critical. Avoid angularity beyond 2 degrees.

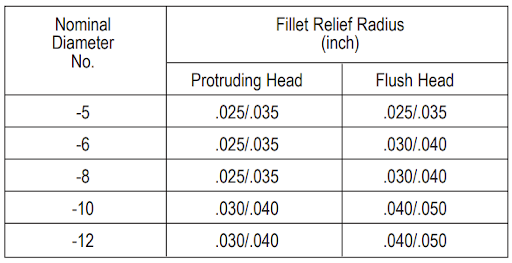

- Deburr all hole edges in the stack-up and provide head-to-shank fillet relief

- Ensure that countersink pilots are not undersized, which can cause eccentricity problems and cosmetic issues.

- Lubricating drills reduce flank wear, burrs, and effort.

Applied Fasteners and Tooling – Innovative Aircraft Tools

Supporting a range of specialty Eddie Bolt installation and removal tooling, including pneumatic and hand tools, Applied Fasteners and Tooling help you with check gauges and spare parts for maintenance and repair.

Committed to maintaining a high standard of service as distributors of fasteners and tools for the Aerospace, Military, Defence, Space, Marine, Industrial, Mining, Transport, and Motorsport markets, we adhere to the AS9120 Quality System. We ensure supplier performance, on-time delivery, and quality.

Whether you’re looking for an Inspection Gauge, Ratchet Wrench, Square Drive Socket, or Curved Driver, we prepare you for your latest aerospace project. Contact us today for a competitive quote on honeycomb inserts, a cable drum dispenser, motorsport fasteners, Avibank Ball Lok Pins, cable tie mounts, or anything you need for your next engineering project!